|

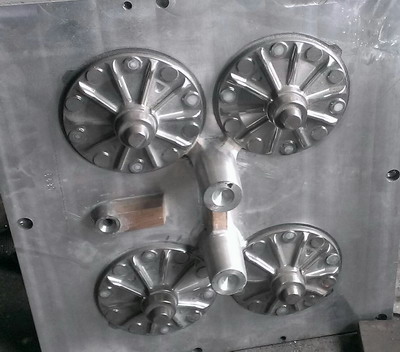

1. Making Metal Pattern

Iron patterns are the necessary tooling for

automatic molding line, so the pattern cost is high

comparatively. The metal patterns are made by CNC

milling machine, so the dimensional tolerance and

surface quality are very good.

2. Automatic Molding

The automatic molding line can perform the molding

process automatically, only need one worker to

operate the machine.

3. Melting Iron

During molding, the electrical furnaces will start

to melt the irons. The raw materials for ductile

iron and grey iron include pig iron, scrap returns,

and alloy agents. Dandong Foundy has four 1.5 tons

furnaces.

4. Inoculation Treatment (Nodulizing)

After melting, the workers will move the large

pouring ladle to the ductile iron inoculation

treatment station. After automatic nodulizing, the

raw iron will become ductile iron. Dandong Foundry

uses this station to guarantee the stable

inoculation quality. The traditional inoculation

method can not reach high nodulizing quality.

5. Pouring

After nodulizing treatment, the workers will pour

the liquid iron in the large pouring ladle into

small pouring ladles. Then, each worker takes one

small ladle to pour into the sand molds.

6. Sand Blasting and Grinding

When the castings removed out of sand molds, the

iron castings will be cleaned by sand blasting

equipments. Then, the workers will grind the gating

heads, and parting lines.

7. Machining

After cleaning and grinding, the castings will be

taken to the machining workshop. The workers will

machine them according to the machining drawings and

requirements. Dandong Foundry can complete the rough

and finish machining works in-house.

8. Machined Casting Parts

After machining, the casting parts will be

completed. Then, they will be inspected and packed

for delivery and shipment.

|