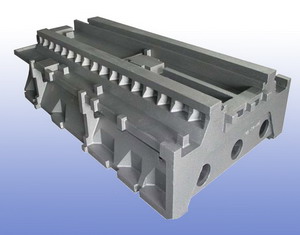

Cast iron could be used for many machinery housings and bases because it is extremely stable in its structure.

Below is the reason for using cast iron to make machinery lathe parts:

1. Cast Iron material is competitive than cast steel.

2. Cast iron is with exceptional damping capacity.

Cast iron, special gray cast iron is used for custom lathe parts, because the material has the ability to absorb vibration. The damping capacity can help the cast iron lathe bed, lathe support or base stable to assure the lathe machining dimensional accuracy.

3. Cast iron is commonly used for machinery housings or bases due to the stable structure of the material. It is also known for holding its shape when it is subjected to contraction and expansion due to temperature fluctuations.

4. Cast iron consists of graphite flakes that have sharp edges which act as stress raisers in tension. This shape makes cast iron low in tensile strength and ductility, but it still has high compressive strength.

5. The morphology of graphite as a flake in grey cast iron enables to absorb both compressive and vibrational loads without initiating a crack. In general, vibration can be critical in machinery and can cause an unsatisfactory operation or even failure.

cast iron CNC machine parts lathe bed casting

|