| |

Gray iron, or grey cast iron, is a type of cast iron that has a graphite microstructure. It is named after the gray color of the fracture it forms.

It is used for housings where the stiffness of the component is more important than its tensile strength, such as internal combustion engine cylinder blocks, pump housings, valve bodies, electrical boxes, counter weights and decorative castings. Grey cast iron's high thermal conductivity and specific head capacity are often exploited to make cast iron cookware and disc brake rotors.

Structure

A typical chemical composition to obtain a graphitic microstructure is 2.5 to 4.0% carbon and 1 to 3% silicon by weight. Graphite may occupy 6 to 10% of the volume of grey iron. Silicon is important to making grey iron as opposed to white cast iron, because silicon is a graphite stabilizing element in cast iron, which means it helps the alloy produce graphite instead of iron carbides; at 3% silicon almost no carbon is held in chemical combination with the iron.

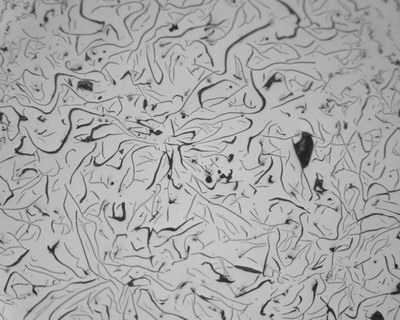

The graphite takes on the shape of a three-dimensional flake. In two dimensions, as a polished surface will appear under a microscope, the graphite flakes appear as fine lines. The tips of the flakes act as preexisting notches; therefore, it is brittle. The presence of graphite flakes makes the Grey Iron easily machinable as they tend to crack easily across the graphite flakes. Grey iron also has very good damping capacity and hence it is mostly used as the base for machine tool mountings.

Microstructure of Gray Cast Iron

Physical and Mechanical Properties

Item according to DIN EN 1561 |

Measure |

Unit |

EN-GJL-150 |

EN-GJL-200 |

EN-GJL-250 |

EN-GJL-300 |

EN-GJL-350 |

EN-JL 1020 |

EN-JL 1030 |

EN-JL 1040 |

EN-JL 1050 |

EN-JL 1060 |

Tensile Strength |

Rm |

MPA |

150-250 |

200-300 |

250-350 |

300-400 |

350-450 |

0.1% Yield Strength |

Rp0,1 |

MPA |

98-165 |

130-195 |

165-228 |

195-260 |

228-285 |

Elongation Strength |

A |

% |

0,3 – 0,8 |

0,3 – 0,8 |

0,3 – 0,8 |

0,3 – 0,8 |

0,3 – 0,8 |

Compressive Strength |

σdB |

MPa |

600 |

720 |

840 |

960 |

1080 |

0,1% Compressive Strength |

σd0,1 |

MPa |

195 |

260 |

325 |

390 |

455 |

Flexural Strength |

σbB |

MPa |

250 |

290 |

340 |

390 |

490 |

Schuifspanning |

σaB |

MPa |

170 |

230 |

290 |

345 |

400 |

Shear Stress |

TtB |

MPa |

170 |

230 |

290 |

345 |

400 |

Modules of elasticity |

E |

GPa |

78 – 103 |

88 – 113 |

103 – 118 |

108 – 137 |

123 – 143 |

Poisson number |

v |

– |

0,26 |

0,26 |

0,26 |

0,26 |

0,26 |

Brinell hardness |

|

HB |

160 – 190 |

180 – 220 |

190 – 230 |

200 – 240 |

210 – 250 |

Ductility |

σbW |

MPa |

70 |

90 |

120 |

140 |

145 |

Tension and pressure change |

σzdW |

MPa |

40 |

50 |

60 |

75 |

85 |

Breaking Strength |

Klc |

N/mm3/2 |

320 |

400 |

480 |

560 |

650 |

Density |

|

g/cm3 |

7,10 |

7,15 |

7,20 |

7,25 |

7,30 |

|

|