| |

Our Dandong Foundry can produce gray iron castings in different grades, such as HT100, HT150, HT200, HT250, HT300 and HT350.

Gray Iron, named so because of the gray color it displays when fractured. This is primarily due to the presence of graphite within. Based on its weight, cast iron is the most widely used cast material. It is also the most common of the cast irons used. Gray iron castings offer a multitude of uses.

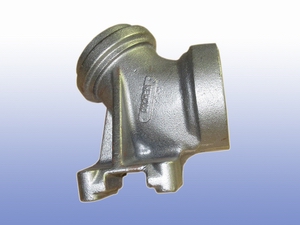

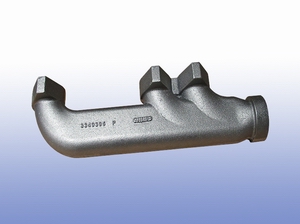

When stiffness is more important than tensile strength, Cast Iron's ability to resist deformation in response to an applied force such as internal combustion, it is ideal for making components such as engine blocks, valve bodies, pump housings, etc.

Very common as an engineering alloy, Gray Iron is typically low in cost. It is also machine friendly, this is a result of the graphite becoming a lubricant, which allows the cut to become lubricated and the chips to breakup. Other benefits of using Gray Iron is galling, wear resistance, damping capacity, less solidification shrinkage, easy to weld, etc.

Because of some of Gray Iron's characteristics, such as, strength and ductility, its shock and impact resistance are nearly non-existent when compared to more modern iron alloys.

Grey iron casting is used in many market segments, including automotive, agricultural, machinery building, electronics, irrigation, ventilation, architecture, construction and transportation industries.

gray cast iron pipe for diesel engine

gray cast iron manifold |

|