| |

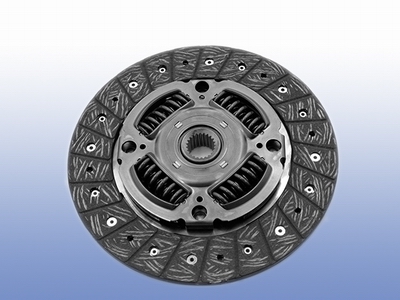

Gray iron castings have been widely used for automotive industries, such as brake drums and clutch plates.

Automotive brake drums and clutch plates for heavy-duty service are considered as special cases. Typical chemical analyses and mechanical properties are listed in Table 1 and Table 2.

Heavy-duty irons for such service require high carbon contents for resistance to thermal shock and to minimize heat checking. To maintain strength levels specified for Grades G3500b and G3500c normally requires alloying due to their high carbon contents.

Table 1 Usual Composition of Brake Drums and Clutch Plates for Special Service |

Chemical Composition, % |

Grade

G2500a |

Grade

G3500b |

Grade

G3500c |

Carbon, total (mandatory) |

3.40 min |

3.40 min |

3.50 min |

Silicon (as required) |

1.60–2.10 |

1.30–1.80 |

1.30–1.80 |

Manganese (as required) |

0.60–0.90 |

0.60–0.90 |

0.60–0.90 |

Sulfur, max |

0.12 |

0.12 |

0.12 |

Phosphorus, max |

0.15 |

0.15 |

0.15 |

Alloys |

as required |

as required |

as required |

Table 2 Typical Mechanical Properties |

Mechanical Properties |

Grade

G2500a |

Grade

G3500b |

Grade

G3500c |

Tensile strength, min:

Psi

kgf/mm |

25 000

17.5

|

35 000

24.5

|

35 000

24.5

|

Transverse strength, min:

lb

kg |

2000

910

|

2400

1090

|

2400

1090

|

Deflection, min:

in.

mm |

0.17

4.3

|

0.24

6.1

|

0.24

6.1

|

Hardness, HB |

170–229 |

207–255 |

207–255 |

Brinell indention diameter, mm |

4.6–4.0 |

4.2–3.8 |

4.2–3.8 |

See Table 3 for microstructure requirements.

Table 3 Brake Drums and Clutch Plates for Special Service |

Grade |

Carbon min, %A |

Casting Hardness |

Microstructure |

Graphite |

Matrix |

G2500a |

3.40 |

HB 170-229 |

Type VII, size 2–4 |

lamellar pearlite |

4.6–4.0 BID or as agreed |

A distribution |

ferrite if present not to exceed 15% |

G3500b |

3.40B |

HB 207-255 |

Type VII, size 3–5 |

lamellar pearlite |

4.2–3.8 BID or as agreed |

A distribution |

ferrite or carbide if present not to exceed 5% |

G3500c |

3.50B |

HB 207-255 |

Type VII, size 3–5 |

lamellar pearlite |

4.2–3.8 BID or as agreed |

A distribution |

ferrite or carbide, if present not to exceed 5% |

A The chemical analysis for total carbon shall be made on chilled pencil-type specimens or from thin wafers approximately 1/32 in. (0.8 mm) thick cut from test coupons. Drillings are not reliable because of the probable loss of graphite.

B Grades G 3500b and G 3500c normally require alloying to obtain the specified hardness at the high carbon levels specified.

Following are suggested grades for brake drums and clutch plates according to types of service:

Grade Suggested Usage

G2500a Brake drums and clutch plates for moderate service requirements, where high carbon iron is desired to minimize heat checking.

G3500b Brake drums and clutch plates for heavy-duty service where both resistance to heat checking and higher strength are definite requirements.

G3500c Extra-heavy-duty service brake drums.

automotive brake drums

automotive clutch plates |

|