There are many factors which will affect the quality of ductile iron castings, including chemical composition, spheroidization and heat treating.

Every foundry will make ductile iron by the way that works best for them. The engineer may notice that almost all ductile iron standards don't specify a chemistry requirement. This is because the microstructure and mechanical properties can be achieved in different ways. Specifically, the mechanical properties can be affected by:

-

Changing the chemistry

-

Heat treating techniques

Charge materials

Scrap chemistry and quality have a big effect on ductile iron quality. This is because the level of tramp elements affects the microstructure and mechanical properties. One recommendation is to use pig iron with low tramps.

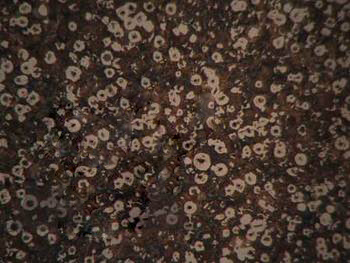

85% pearlitic microstructure

Ductile Iron Treatment

The method of treatment affects the quality of the iron. Ideally, the method used would allow the reaction to be very controlled. It would lead to a high Mg recovery, as well as a good nodule quality and high nodule count. It's important to work closely with the treatment alloy supplier to determine what works best for the foundry process.

Heat Treatment

Altering the microstructure and mechanical properties can be done by heat treating. A casting alloyed to meet the 65-45-12 specification can be heat treated to meet the 60-40-18 material properties. The 65-45-12 material can also be heat treated to meet the 80-55-06 properties. Heat treating to achieve properties improves the delivery time and the final cost.

55% ferritic typical of 65-45-12

|