Our Dandong Foundry can produce ductile iron castings in different grades, such as QT400-15, QT400-18, QT450-10, QT500-7 and QT600-3.

Ductile Iron, also known by many other names such as, ductile cast iron, nodular cast iron, spheroidal graphite iron, etc. Because of its nodular graphite rich inclusions, it is known for its fatigue and impact resistance. Ductile iron castings are strong.

What truly defines the group of materials that make up Ductile Iron is the structure of its graphite. Unlike the graphite flakes in Gray Iron, the structures of the graphite in Ductile Iron are nodules. These rounded nodules inhibit the formation of cracks. This characteristic provides increased ductility; hence the name Ductile Iron.

Benefits of Ductile Iron Casting:

-

It has superior castability and machinability.

-

It has an excellent strength to weight ratio.

-

Cost of ductile iron casting is lower than steel castings.

-

Compared to grey iron casting, ductile iron has much more impact and fatigue resistance, due to its nodular graphite inclusions.

-

Ductile iron casting provides a designer with an exceptional combination of toughness, low cost manufacturing, and reliability.

In the automotive industry, it is used for components that require a material other than steel but is stronger than aluminum. For projects that are large and complex and require extreme fatigue loads, nodular cast iron is used. Other uses for ductile iron castings include oil well pumps, Class 8 trucks, hubs and structural parts, etc.

The followings are some castings produced by ductile iron:

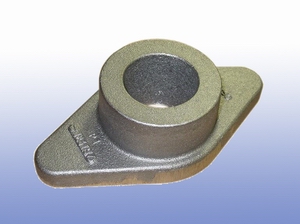

ductile iron bracket

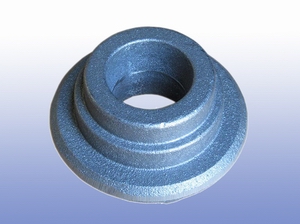

ductile iron stuffing gland

ductile iron bearing housing square

ductile iron bearing housing round |