Metallographic inspection is a very important material quality inspection method for ductile iron castings (SG iron castings), it can also judge the ductile iron material grades.

If the metallographic inspection result is good, then the ductile iron material quality should be good, otherwise, the quality may not be good, or the material grade may not be correct.

However, as for the unprofessional inspectors and buyers, you may not understand the metallographic photos very well.

The followings are some photos and guide, which will help you to learn these knowledge quickly and easily. All these photos and information are made by Dandong Foundry in China, so please respect our copy right.

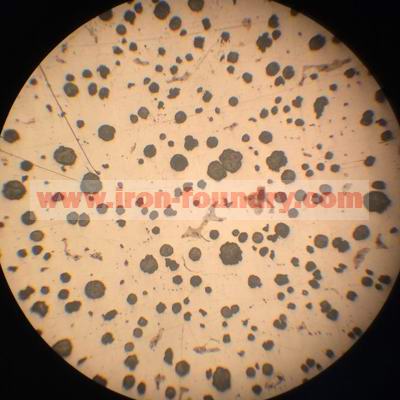

1. How to judge nodularity, the rate of spheroidization

Nodularity is the percentage of graphite balls. The black balls on the following photos are the graphite balls. More balls will be better. So, nodularity is the direct and the most important factor to casting material quality.

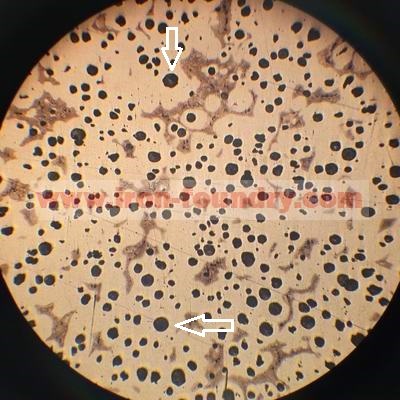

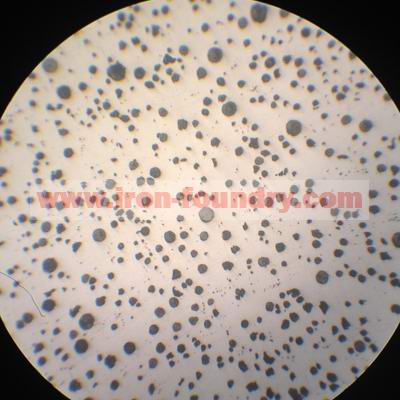

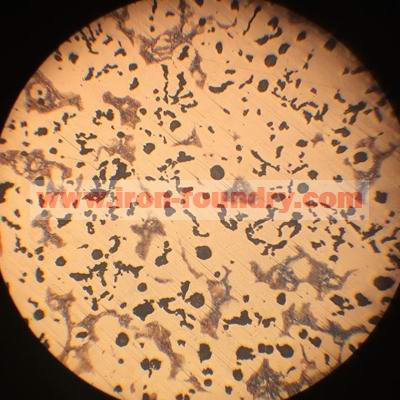

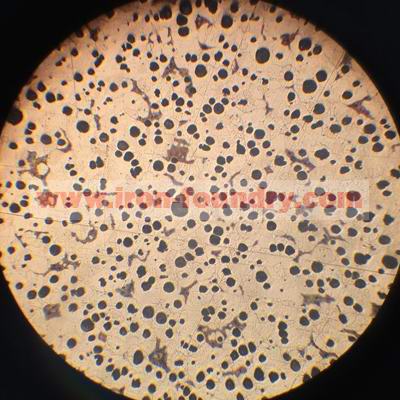

High Quality Ductile Iron:

The following two photos showing the nodularity higher than 80%, so its nodularity is very good, they are high quality ductile iron material grades, our dandong foundry could produce these materials.

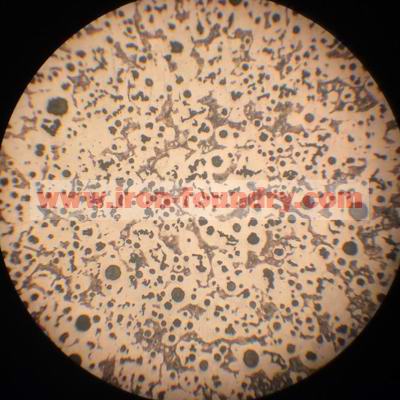

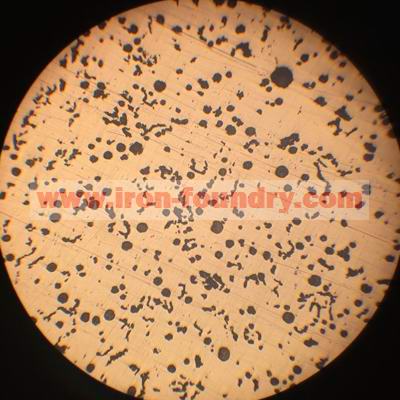

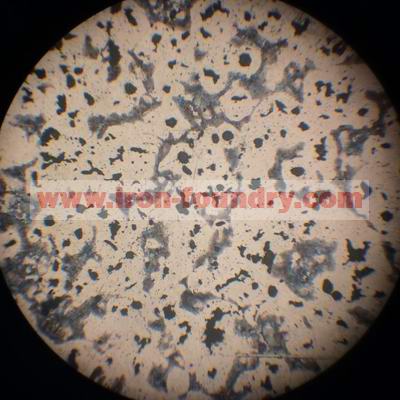

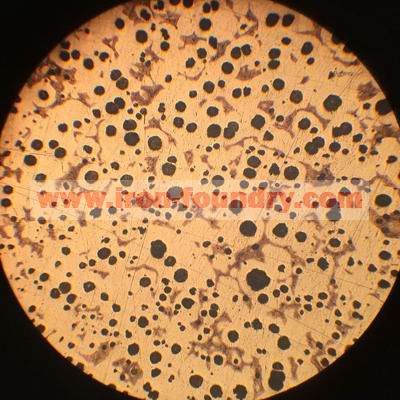

Normal Quality Ductile Iron:

The following two photos are showing the nodularity higher than about 70%, you could see some worm shape graphite (the black worm), and also some graphite balls become not very round. This level of nodularity is showing the normal or poor ductile iron quality.

If you required high quality material, then this kind of quality will not be qualified, however, as for the most of products, this level could meet the mechanical requirements, such as tensile strength and elongation.

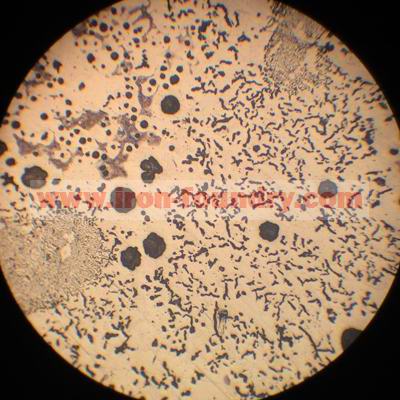

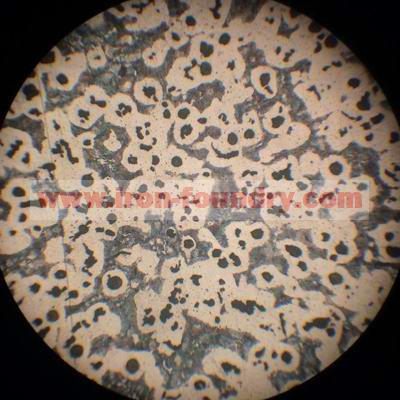

Low Quality Ductile Iron:

The following two photos are showing the low quality of ductile iron material. The nodularity will be about 50% or lower. There are many worm shape and flower shape graphite balls, which are very harmful to its mechanical properties. This material level is low and unqualified.

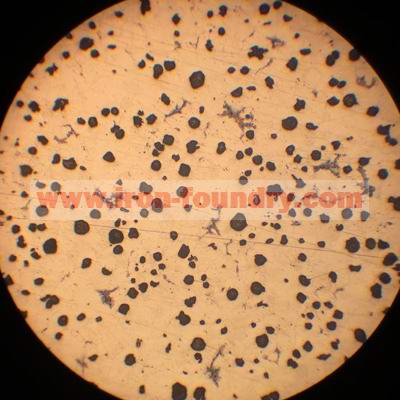

Very Low Quality Cast Iron:

The following two photos are showing very low and very poor ductile iron materials. The graphite balls are very few, and there are many strange shapes of graphite. The material is fragile, so unqualified at all.

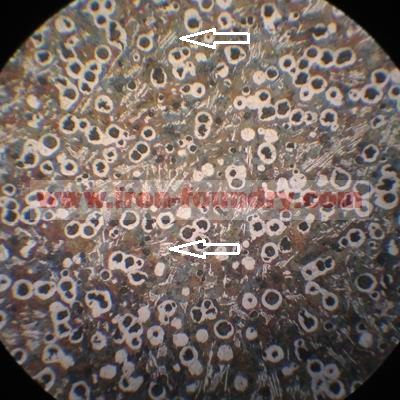

2. How to judge the content of pearlite

The proportion of pearlite is also important. It will affect the tensile strength of ductile iron (SG iron). High content of pearlite will mean high tensile strength, in other words, high material grades, such as ASTM A536 120-90-02, 100-70-03, 80-55-06, 80-60-03, 70-50-05. Low content of pearlite will mean low high tensile strength, such as ASTM A536 60-45-12, 60-40-18.

However, too high percentage of pearlite will mean very low elongation, so not good to its ductility. Therefore, our Dandong foundry has paid attention to control the content of pearlite for many years.

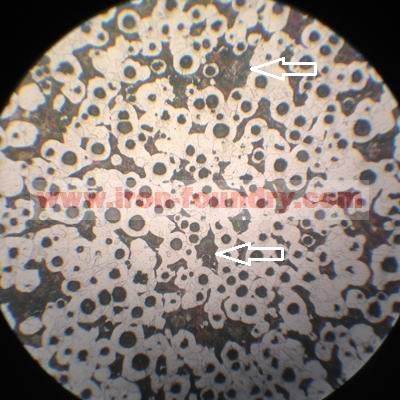

High Content of Pearlite:

The following two photos are showing over 50% content of pearlite. The round black balls are graphite balls, the white areas around graphite balls are ferrite, the other brown areas are pearlite. This level is good for high tensile strength ductile iron grades.

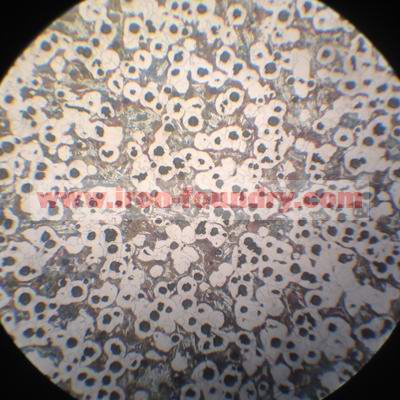

Normal Content of Pearlite:

The following two photos are showing the normal percentage of pearlite, only about 30% or lower percentage. This level of pearlite is good for middle grades of ductile iron, such as ASTM A536 70-50-05, 60-45-12, 60-40-18.

Low Content of Pearlite:

The following two photos are showing the about 10% or lower percentage of pearlite, which are good for low grades of ductile iron, such as ASTM A536 60-45-12 and 60-40-18. These grades have very high elongation, so good ductility.

3. How to judge the free carbide of ductile iron, SG iron

Free carbide is very harmful to ductile iron, because it will cause cast iron fragile. The following photos are showing some free carbide. You could see the white free carbide in the areas of pearlite. They look like bone or grass. The free carbide is the reason of chilled iron.

Our dandong foundry does not like free carbide, so we have some experience to avoid them, or remove them by proper heat treatment.

|