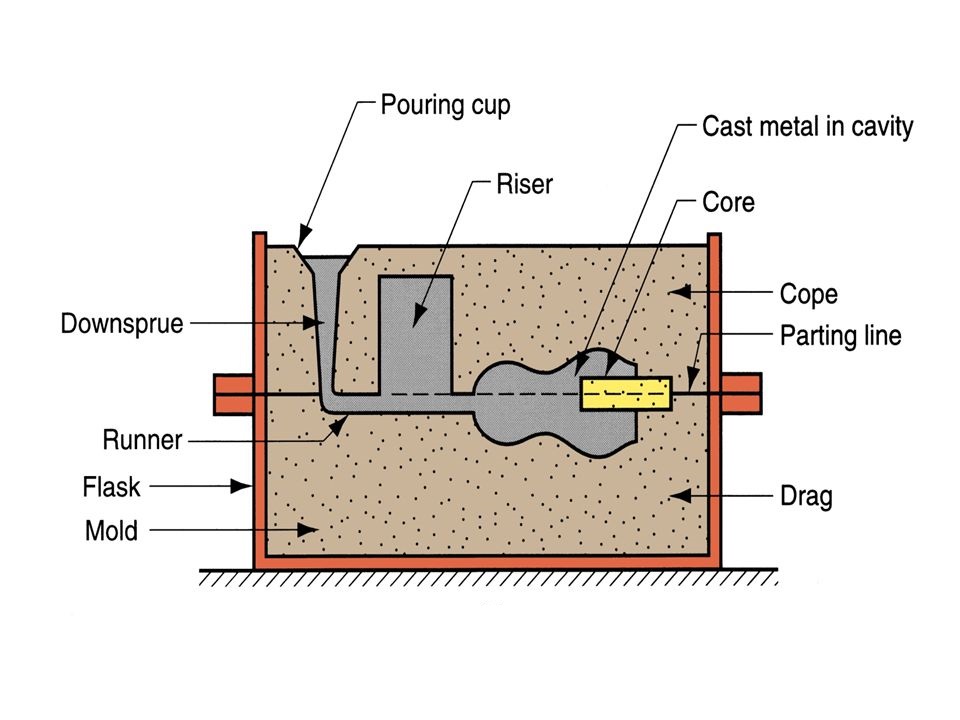

The common terminology includes flask, pattern, parting line, bottom board, moulding sand, facing sand, backing sand, pouring basin, core, sprue, runner, chills, chaplet and riser.

(1) Flask:- The Flask is the box that contains the moulding aggregate.

(2) Pattern:-It is the replica of the final object to be made with some modification.

(3) Parting Line:-This is dividing line between two parts of flask that makes the sand moulds.

(4) Bottom Board:- This is normally made of wood which is used to support the one end of the flask.

(5) Facing Sand:- The small amount of carbonaceous sand material sprinkle on the internal mould surface of cavity to give better surface finish to the casting.

(6) Moulding Sand:- It is freshly prepare refractory use for making the mould cavity.

(7) Backing Sand:- It is the bulk of the sand used to back up the facing sand & to fill up the volume of the flask.

(8) Pouring Basin:- A small funnel shaped cavity at the top of mould in to inch the molten metal is poured.

(9) Core:- A core is used in Casting and moulding process to produce internal hollow cavities in final product.

(10) Sprue:- It is vertical cavity in the moulds to flow the molten metal from the pouring basin.

(11) Runner:- The pass way in the parting line through which molten metal regulated before they reach to mould cavity.

(12) Chills:- Chills are metallic object which are placed in mould to increase the cooling rate of the casting.

(13) Chaplet:- Chaplets are used to support the cores inside the mould cavity to take care of its own weight and overcome the metallostatic force.

(14) Riser :- It is reservoir of molten metal provided in casting show that metal can flow back into the more cavity there is a reduction in volume of metal due to solidify.

|