During the quality inspection to cast iron dental chair brackets, our Dandong Foundry usually focused on the following aspects:

1. Mold shift defect

Mold shift defect will cause both the center hole and the side position to be offset during the machining. Therefore, if the dental chair bracket has the mold shift defect, it must be scrapped.

2. Raised mold defect

Raised mold defect will cause the bottom plane of the dental chair bracket to be uneven seriously, which must be discarded if happened.

3. Defects on machining surface

If there are slag inclusion, shrinkage defects or other casting defects on the machining surfaces, the dental chair brackets must be discarded.

4. Surface inspection

The surface of the dental chair bracket must be polished to be clean without any defect.

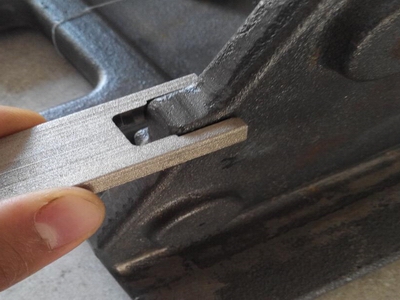

5. Using inspection tools

The quality inspectors in our foundry usually use inspection tools to check whether the machining position or wall thickness of the dental chair bracket is qualified.

Inspectoin to Dental Chair Bracket Casting

|