There are many advantages that the casting process offers when compared to the custom metal fabrication process.

For example, welding during the fabrication process creates more stress and distortion due to localized heat. Casting creates a more homogeneous microstructure as there is no heat affected zone.

In addition, a higher-quality end product can result from the casting process. This is due to a number of factors:

-

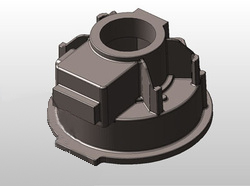

The ability to transition material thicknesses and add a number of radii that reduce stress

-

Once a pattern is approved each casting is the same, versus a fabrication where human error is involved and parts can be assembled incorrectly

-

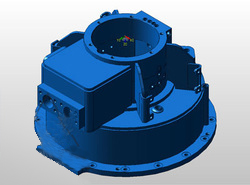

It's possible to cast complex dimensions, shapes and sizes

-

Converting a steel fabrication to a ductile iron casting also offers machinability advantages

-

Ductile iron has greater vibration dampening properties

There are also significant cost savings to be realized due to the following:

-

Casting eliminates many processes, reducing production time.

-

Multiple castings can be made at one time.

-

Less skill is required as casting production can be more automated, as opposed to the skills required for welding and fabrication.

-

More efficient use of material as "drops/crops" are not part of the material cost – material costs are lower when using ductile iron as opposed to steel fabrications.

When considering the custom metal fabrication process versus the casting process, it's evident that there are significant advantages that the casting process offers both in terms of quality control and cost savings.

Of course, the steel fabrication has some advantages too, so you should choose the proper process for your products. |