| |

FGL250 is a material grade of gray cast iron defined in France standard NF A32-101. FGL250 is the most common cast iron and the most widely used cast material based on weight.

The followings are the applications, chemical composition, technological and physical values, mechanical properties, and equivalent grades for NF A32-101 FGL250 gray cast iron.

Application for NF A32-101 FGL250 Gray Cast Iron:

FGL250 gray cast iron is used for housings where the stiffness of the component is more important than its tensile strength, such as internal combustion engine cylinder blocks, pump housings, valve bodies, electrical boxes, and decorative castings. Grey iron also has very good damping capacity, hence its use as the base for machine tool mountings.

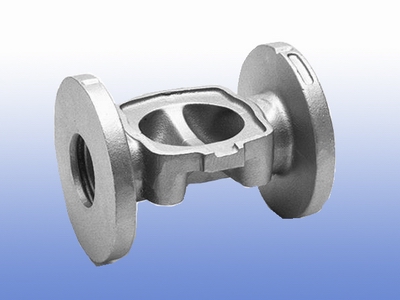

The following castings are made of FGL250 gray cast iron by our Dandong foundry.

Chemical Composition for NF A32-101 FGL250 Gray Cast Iron:

No any requirement about chemistry in the NF A32-101 standard, but our Dandong Foundry will suggest the chemical composition of FGL250 gray cast iron according to our experience in casting industry, just for your reference.

C |

Si |

Mn |

P |

S |

2.8-3.3% |

1.2-1.7% |

0.8-1.2% |

P ≤ 0.15% |

S ≤ 0.12% |

Technological and physical values:

The followings are the technical and physical values for gray cast iron EN-GJL-250, which should be equivalent to FGL250

Item according to DIN EN 1561 |

Measure |

Unit |

EN-GJL-250 |

Equal to NF A32-101 |

|

|

FGL250 |

Tensile Strength |

Rm |

MPA |

250-350 |

0.1% Yield Strength |

Rp0,1 |

MPA |

165-228 |

Elongation Strength |

A |

% |

0,3 – 0,8 |

Compressive Strength |

σdB |

MPa |

840 |

0,1% Compressive Strength |

σd0,1 |

MPa |

325 |

Flexural Strength |

σbB |

MPa |

340 |

Schuifspanning |

σaB |

MPa |

290 |

Shear Stress |

TtB |

MPa |

290 |

Modules of elasticity |

E |

GPa |

103 – 118 |

Poisson number |

v |

– |

0,26 |

Brinell hardness |

|

HB |

190 – 230 |

Ductility |

σbW |

MPa |

120 |

Tension and pressure change |

σzdW |

MPa |

60 |

Breaking Strength |

Klc |

N/mm3/2 |

480 |

Density |

|

g/cm3 |

7,20 |

Casting involved mechanical properties:

The following mechanical properties are for gray cast iron EN-GJL-250, which should be equivalent to FGL250.

Item according to DIN EN 1561 |

Tensile Strength cast in apart test piece [MPa] |

Wall thickness [mm] |

Tensile Strength in moded test piece

[MPa] Min. |

Expectation Values in the casting |

from |

to |

Tensile Strength [MPa] min. Values |

Brinell hardness [HB] Max. Values |

EN-GJL-250 |

250 – 350 |

5

10

20

40 |

10

20

40

80 |

250

–

210

190 |

270

225

195

170 |

250

230

215 |

Cross reference table for Cast iron FGL250 (NF A32-101) and its European equivalent EN-GJL-250 (EN-JL1040) (EN)

EU

EN |

USA

- |

Germany

DIN,WNr |

Japan

JIS |

France

AFNOR |

England

BS |

Italy

UNI |

Belgium

NBN |

Spain

UNE |

EN-GJL-250 (EN-JL1040) |

250/275

35

35B

40

40B |

0.6025

GG25 |

FC250 |

FGL250 |

250

260

Grade220

Grade260 |

G25 |

FGG25 |

FG25 |

China

GB |

Sweden

SS |

Bulgaria

BDS |

Hungary

MSZ |

Poland

PN |

Romania

STAS |

Austria

ONORM |

Norway

NS |

Australia

AS |

HT25-47

HT250 |

01-25-00

0125 |

Vch25 |

OV25 |

Z125 |

FC250 |

GG25 |

SJG250 |

T260 |

Russia

GOST |

Inter

ISO |

India

IS |

Netherlands

NEN |

Denmark

DS |

Taiwan

- |

Luxembourg

- |

COPANT

- |

SCH25 |

250

JL250 |

FG260 |

GG25 |

GG30 |

FC250 |

FGG25 |

FG250 |

|

|