ASTM A536 is the American standard specification for ductile iron castings, the main material grades including:

Grade 60-40-18

Grade 60-42-10

Grade 65-45-12

Grade 70-50-05

Grade 80-55-06

Grade 80-60-03

Grade 100-70-03

Grade 120-90-02

This specification covers castings made of ductile iron, also known as spheroidal or nodular cast iron, or S.G. iron. The followings are the main content for mechanical, chemical requirements, and also quality requirements.

1. Mechanical Requirements

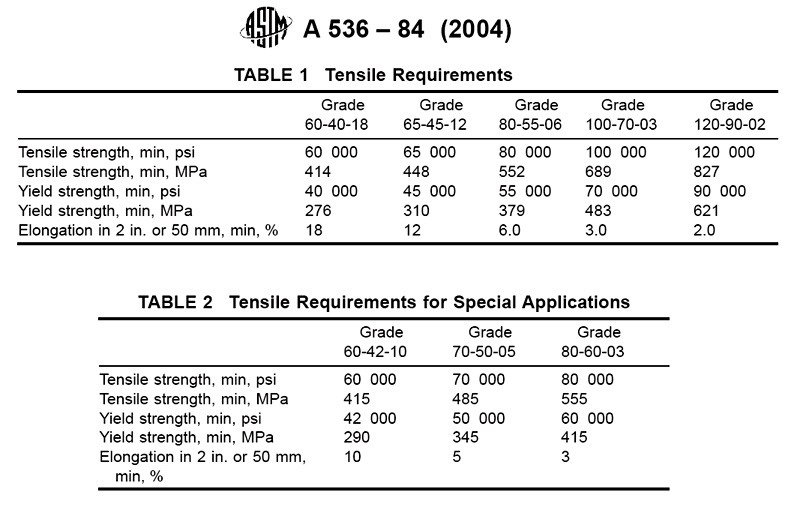

The iron represented by the test specimens shall conform to the requirements as to tensile properties presented in Tables 1 and Table 2.

The irons listed in Table 1 cover those in general use, while those listed in Table 2 are used for special applications (such as pipes, fittings, etc.).

The yield strength shall be determined at 0.2 % offset by the offset method. Other methods may be used by mutual consent of the manufacturer and purchaser.

In this standard, it is clear that the ductile iron castings can be taken as qualified if they could meet the mechanical requirements, including tensile strength, yield strength and elongation. So, mechanical requirements are the main material quality yard for ductile iron castings.

The suppliers should have the capability to do the mechanical testing, and issue the testing report to purchaser, so to prove their castings qualified.

2. Heat Treatment

The 60-40-18 grade will normally require a full ferritizing anneal. The 120-90-02 and the 100-70-03 grades generally require a quench and temper or a normalize and temper, or an isothermal heat treatment. The other two grades can be met either as-cast or by heat treatment. Ductile iron, which is heat treated by quenching to martensite and tempering, may have substantially lower fatigue strength than as-cast material of the same hardness.

Actually, as for the most of ductile iron grades, the heat treatment is not necessary if the casting manufacturer could control the spheroidizing (nodulizing) process very well. However, if they can not, then the certain heat treatment will be necessary for 60-40-18 and 120-90-02.

So, the purchaser does not have to require the heat treatment if the foundry could meet the mechanical requirements.

3. Chemical Requirements

It is the intent of this specification to subordinate chemical composition to mechanical properties; however, any chemical requirements may be specified by agreement between the manufacturer and the purchaser.

In any standard, there is no specific chemical requirements to ductile iron, so if the purchaser has the special requirement, then should advise the foundry in advance, otherwise, leave it alone. The casting manufacturer will consider how to adjust the chemical composition to meet the mechanical requirements.

4. Special Requirements

When specified in the contract or purchase order, castings shall meet special requirements as to hardness, chemical composition, microstructure, pressure tightness, radiographic soundness, magnetic particle inspection dimensions, and surface finish.

If there is special requirement, the purchaser should advise the foundries in advance, otherwise, it may cause loss, price increasing or dispute later.

5. Quality and Defects

The castings shall be smooth, free of injurious defects, and shall conform substantially to the dimensions of the drawing or pattern supplied by the purchaser. Castings shall not have chilled corners or center chill in areas to be machined.

The inside and surface defects are common for ductile iron castings, if you want to know what casting defects look like, please refer to Dandong Foundry's article Casting Defect Photos.

6. Tension Test Specimen

The standard round tension test specimen with a 2-in. or 50-mm gage length shown in Fig. 5 shall be used, except when the ½-in. (12.7-mm) Y-block coupon is used. In this case, either of the test specimens shown in Fig. 6 shall be satisfactory.

Normally, the casting manufacturer should know the requirement of tension test bar, otherwise, please refer to dandong foundry's article Tension Test Specimen for Gray iron and Ductile Iron Castings.

7. Responsibility for Inspection

Unless otherwise specified in the contract or purchase order, the supplier is responsible for the performance of all inspection requirements as specified herein. Except as otherwise specified in the contract or order, the supplier may use his own or any other facilities suitable for the performance of the inspection requirements specified herein, unless disapproved by the purchaser.

The purchaser reserves the right to perform any of the inspections set forth in the specification where such inspections are deemed necessary to assure supplies and services conform to prescribed requirements. |