| |

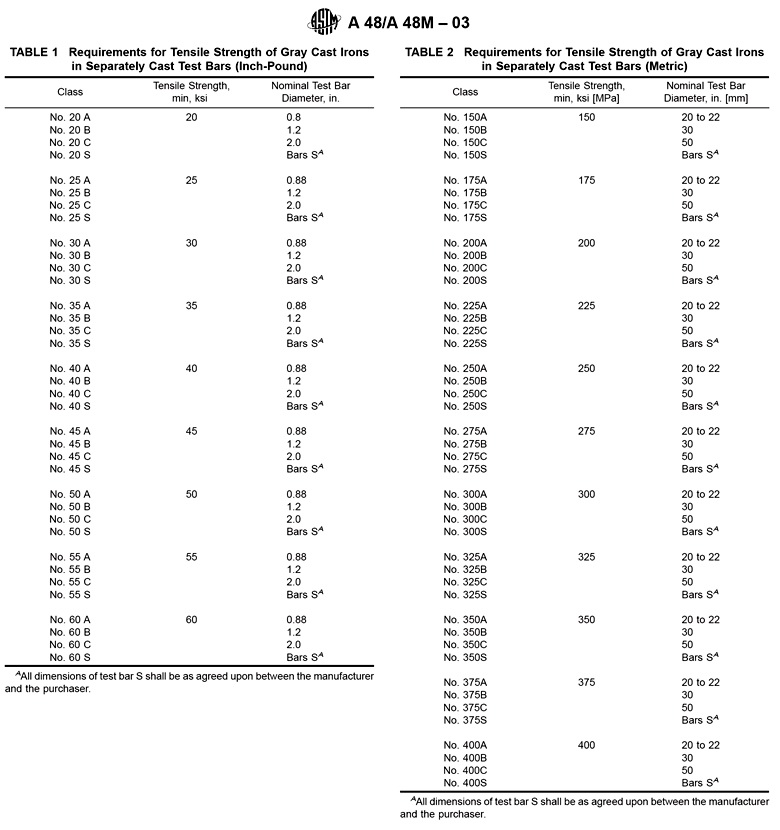

ASTM A48 / A48M Standard Specification for Gray Iron Castings, grades including Class No. 20, 25, 30, 35, 40, 45, 50, 55, 60.

Class No. 20 A, 20 B, 20 C, 20 S,

Class No. 25 A, 25 B, 25 C, 25 S,

Class No. 30 A, 30 B, 30 C, 30 S,

Class No. 35 A, 35 B, 35 C, 35 S,

Class No. 40 A, 40 B, 40 C, 40 S,

Class No. 45 A, 45 B, 45 C, 45 S,

Class No. 50 A, 50 B, 50 C, 50 S,

Class No. 55 A, 55 B, 55 C, 55 S,

Class No. 60 A, 60 B, 60 C, 60 S.

This specification covers gray iron castings intended for general engineering use where tensile strength is a major consideration. Castings are classified on the basis of the tensile strength of the iron in separately cast test bars.

1. Requirements for Tensile Strength

On the above chart, you could see the each material grade has required its min. tensile strength, ksi, so the tensile strength is the most important specification to gray iron castings.

However, there is no need to write the material grades with A, B, C, S for casting foundry, because the A, B, C, S are just the requirements to the test bar.

For example, ASTM A48 Class 20 will be detailed enough for iron foundries, it means the min. tensile strength of gray iron castings must be higher than 20 ksi (138 Mpa).

ASTM A48 Class 20: Min. Tensile Strength 20 ksi (138 Mpa)

ASTM A48 Class 25: Min. Tensile Strength 25 ksi (172 Mpa)

ASTM A48 Class 30: Min. Tensile Strength 30 ksi (207 Mpa)

ASTM A48 Class 35: Min. Tensile Strength 35 ksi (241 Mpa)

ASTM A48 Class 40: Min. Tensile Strength 40 ksi (276 Mpa)

ASTM A48 Class 45: Min. Tensile Strength 45 ksi (310 Mpa)

ASTM A48 Class 50: Min. Tensile Strength 50 ksi (345 Mpa)

ASTM A48 Class 55: Min. Tensile Strength 55 ksi (379 Mpa)

ASTM A48 Class 60: Min. Tensile Strength 60 ksi (414 Mpa)

If you want to know the equal grades for other standards, please refer to Equivalent Grades of Gray Iron and Ductile Iron.

2. Dimensional Requirement

The castings shall conform to the dimensions or drawings provided by the purchaser, or, if there are no drawings, to the dimensions predicted by the pattern equipment supplied by the purchaser.

Normally, the purchaser should provide the 3D drawings and 2D drawings. 3D drawings will be better for making pattern accurately, the 2D drawings will provide detailed dimensional tolerance and machining requirements. So, this will avoid the confusion and misunderstanding, also the drawings are the only standard for dimensions.

If the purchaser does not have drawings, then should provide one original sample. Our Dandong Foundry could scan the sample into 3D drawings, so the dimensions of the sample will be the standard. The problem is, the foundries should ask the purchaser for the tolerance of the key dimensions, because the sample can not show the tolerance range as the drawings.

3. Quality and Defects Requirement

The surface of the casting shall be free of adhering sand, scale, cracks, and hot tears, as determined by visual examination.

No repairing by plugging or welding of any kind shall be permitted unless written permission is granted by the purchaser.

Normally, the foundry should have enough experience to deal with the defects. However, when defects appeared, the foundry should discuss with the purchaser to confirm if the plugging and welding could be allowable.

The defects on the surface and inside areas are inevitable for metal castings, so it is important for the foundries have good quality inspection and timely communication with clients. If you want to know what casting defects look like, please refer to Dandong Foundry's article Casting Defect Photos.

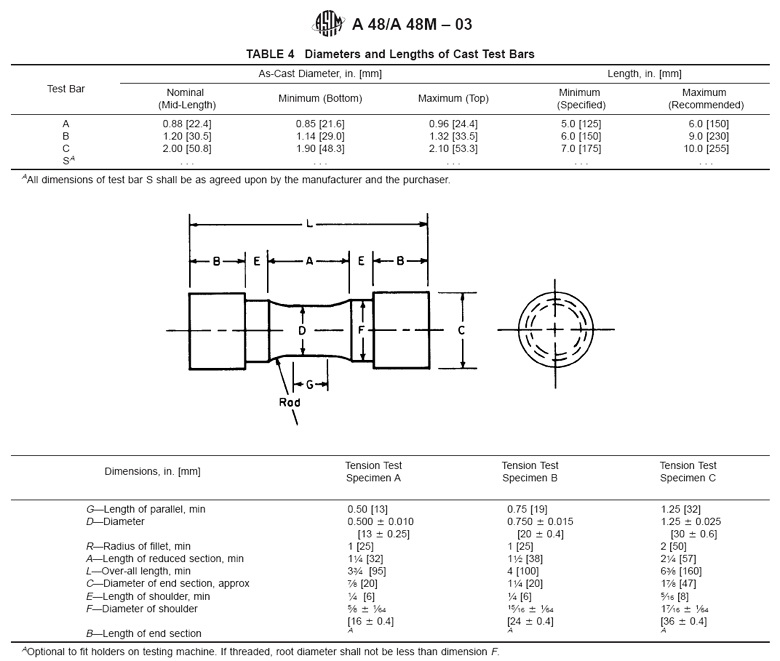

4. Cast Test Bars

Test bars shall be separate castings poured from the same lot as the castings they represent and shall have dimensions as shown in Table 4. Allowance may be made for reasonable pattern draft within the tolerances shown in Table 4. Test bars A, B, and C are all standard test bars in the form of simple cylinders. Test bar S is special and is intended for use where the standard bars are not satisfactory.

In China, most of iron foundries are using similar test bar as "Specimen B", if you want to learn more about the specimen test bar used by our Dandong Foundry, please refer to link Tension Test Specimen for Gray iron and Ductile Iron Castings.

5. Special Requirement

When agreed upon in writing between the manufacturer and the purchaser, it may be necessary for the castings to meet special requirements as to hardness, chemical composition, microstructure, pressure tightness, radiographic soundness, dimensions, surface finish, and so forth.

This means that the purchaser could require more if it is necessary. ASTM A48 is just a standard for the main mechanical property of gray iron castings. If the purchaser has the special requirement as the above mentioned, then should advise the manufacturer at the beginning.

6. Mechanical Properties of Gray Iron Castings

Gray iron castings in Class 20, Class 25, Class 30 and Class 35 are characterized by excellent machinability, high damping capacity, low modulus of elasticity, and comparative ease of manufacture.

Gray iron castings in Class 40, Class 45, Class 50, Class 55 and Class 60 are usually more difficult to machine, have lower damping capacity and a higher modulus of elasticity, and are more difficult to manufacture.

The higher grade means higher tensile strength, higher hardness, the higher prices and production difficulties, so you must know what material grade is suitable or enough for your projects, no need to pursue the highest grade.

|

|