Iron Castings

Iron castings include grey iron

castings, ductile iron

castings and alloy iron castings according to the different

material grades. The followings are some casting products from

Dandong Foundry in China.

1. Axle support for tractors.

The casting was produced by grey cast iron

ASTM A48 class 35, e.g. GG25. This material grade has

good tensile strength and wear resistance. We produced them by

normal green sand

casting process with resin sand cores to meet high

requirements to the inside surfaces.

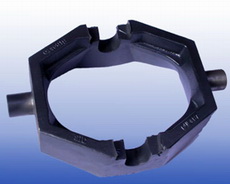

2. Cradle bracket for engineering trucks.

Cradle brackets are important support for engineering trucks. The

material is ductile iron ASTM A536

65-45-12, e.g. GGG40. As for the

large bracket castings, we used

resin sand casting process. As for the middle and small

brackets, we used automatic

molding line.

Casting defects, especially shrinkage are very harmful for

this product. So, rational gating system is necessary.

3. Brake drums for tractors.

This brake drum is comparatively smaller than those used for trucks.

This casting was used for tractors. The casting material is grey

cast iron G25, e.g. O125. Uniform wall thickness is important for

the dynamic balance, and suitable hardness is import for enlarging

the working life.

4. Butterfly valve body for valves.

We could use green sand and shell

molding processes to produce various butterfly valve bodies.

Green sand casting process is cheaper. Valve bodies could be painted

by normal painting and baking finish painting. Normally the casting

material is ductile iron GGG40 or GGG50.

5. Belt pulley for stone crushers.

Large belt pulley

should be produced by resin sand casting process to meet the

requirements to the dimensional tolerance and casting defects. The

material is nodular iron

GGG40, e.g. EN-GJS-400-15. The shrinkage and sand holes on the

groove positions should be unacceptable since they will be very

harmful to belts. The production costs for belt pulley are higher

than normal iron castings.

6. Collector tube for boilers.

Collector tubes are important to large boilers. The casting material

is a kind of alloy grey cast iron with some content of Cr and Ni

alloy to resist the high working temperature. Thin wall thickness

and large sand core are the key technical problems in the

production. Moreover, sand blasting to the inside cores is also not

easy.

Home |

More Articles |