Cast Iron Castings

Cast iron castings means the metal

castings produced by grey iron, ductile iron and malleable

iron. Dandong Foundry in China has produced over 2000 various types

of cast iron products

in the past fifty years.

1. Ductile iron bracket castings for trucks, tractors and

machinery

These brackets were made by QT400-18, equal to GGG40, 60-40-18.

Brackets are the common parts for engineering trucks and many

machinery. Good material and qualified physical properties are the

key quality issues.

2. Grey iron and ductile iron butterfly valve body castings

Butterfly valve bodies could be produced by both grey iron and

ductile iron. GG20, GG25 and GGG40 are the common material for these

parts. Normally, all surfaces of bodies need to be painted by primer

painting or finish painting. Our factory could produce from DN50 to

DN500 valve bodies.

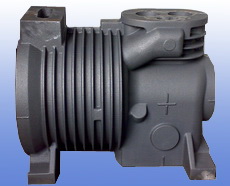

2. Cast iron electric motor housing castings

These motor housings were made by

resin sand casting process to meet the high requirements

to the surface quality and inside structures. The technical

requirements to the gating system and materials are very high for

these types of castings.

4. Grey cast iron plate castings for the workbench of machines

Our foundry has produced these cast iron plates for many years.

Although the material for them is only ASTM A48 class 30 grey iron,

but zero casting defects

to all surfaces and inside is the most difficult technical point.

5. Grey iron furnace grate castings for boilers and stoves

Furnace grate castings were normally produced by

grey cast iron GG15, GG20

and GG25. Sometimes, some alloys were necessary to improve their

high temperature resistant characteristic. Keeping good flatness is

also important for these types of products.

6. Grey iron stove burner castings for industrial and commercial

stoves and baking machines

Our factory has a foundry workshop,

which is using fine green sand as the molding material. Therefore,

we could produce stove burners very well by this sand, at the same

time, the casting prices will be lower than shell molding process.

Home |

More Articles |