| |

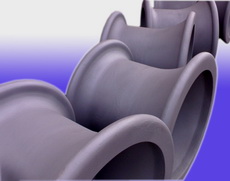

Hydraulic Warping Head GR220

Hydraulic warping

head is used for the hydraulic capstan

in tugboats. The material is mainly grey

cast iron

BS1452 GR220.

There are some iron foundries who have

good experience to produce these capstan

heads.

Dandong Foundry has made many

warping head for the clients overseas.

Herein, I will talk about some quality

issues about them.

Hydraulic warping heads are not

difficult to manufacture since they have

a suitable structure for casting

process, however, as a buyer, you still

need to notice some aspects as

following:

1. Dynamic balance

Dynamic balancing is important for the

warping heads although their rotation

rate is not high. In order to keep the

good dynamic balancing, you should

require your suppliers to use the resin

sand casting process to produce them. By

this casting process, the dimensions and

dynamic balance can be kept.

2. Material Physical

Properties

Since the hydraulic warping head has to

take heavy tensile, so their material

should have good tensile strength and

hardness. Otherwise, it will cause the

potential danger in your application.

Most of iron foundries in China have the

capability to do the tensile strength

and hardness test. So, these issues are

not difficult for suppliers, but just

need them to take them seriously.

Some clients may

choose the ductile iron (SG) as the

material considering the higher tensile

strength and better physical properties.

Such as ductile iron

ASTM A536

60-40-18 or 65-45-12. This is correct

choice. However, if grey iron can meet

your tensile strength requirement, you

do not need to choose the ductile iron

since ductile iron is more costly.

3. Surface Quality

Since most of the surfaces are rough

surfaces, so as a buyer, you should ask

your suppliers to grind them carefully.

Remove all the sharp edges and burrs,

and grind them smoothly. Welding should

be permitted, but the welding positions

should not affect the use.

4. Coating and

Painting

The suppliers should do the anti-rust

primer painting before delivery.

Normally, our clients will paint the

finish painting by themselves, but we

can do the finish painting if you need.

As I said, the hydraulic warping heads

are not difficult to produce, just need

the careful works of the manufacturers.

Home Page |

Casting Products |

Contact Us |

|