| |

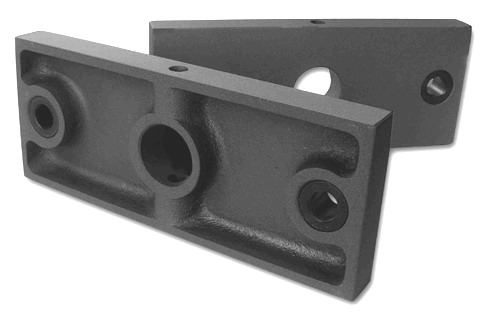

Cast Iron Blocks

Cast iron blocks are one type of

iron castings with block shapes

such as cubic, rectangle, spherical shapes. Most of cast iron blocks

are used as the balance weights or called

counter weights.

Most of cast iron blocks do not have requirements to materials, e.g.

cast iron grades, because

of their application. However, for the cast iron blocks used for

machineries such as tractors, forklifts, trucks and elevators, some

buyers will require the material to be grey cast iron ASTM NO.30,

FC200, GG20 to insure the certain strength for the casting parts.

During my works in Dandong Foundry

in China, I seldom to hear about the cast iron blocks made by

ductile iron.

As for the dimensions of cast iron blocks, usually the flatness and

parallelism are important for the fitness with other parts, but

normally the flat rough surface after grinding should be acceptable,

and machining is not necessary except of special requirements.

The most important issue for cast iron blocks is the price. The

price must be very low because their low requirements and good unit

weight, most of iron foundries in China could produce these types of

castings. So, as for the small cast iron blocks, you should try to

produce them by green sand floor

molding process, but for the large blocks, the

resin sand casting

process will be necessary. Although the resin sand casting prices

have been increased largely because of the increased resin prices,

this process can guarantee the good surface quality, flatness and

parallelism for the large cast iron blocks.

Home Page |

Casting Products |

Contact Us |

|