| |

Ultrasonic examination

for ductile iron, gray iron and cast steel castings

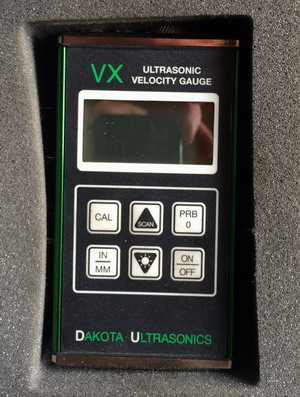

Our Dandong Foundry is using American

Dakota VX Ultrasonic Velocity Gauge to inspect the inside defects

and cast iron quality. This device is also good at inspecting the

cast steel castings.

According to our experience, the casting

material quality could be inspected by this device, because better

material quality will have higher material density, so get higher

ultrasonic speed.

These data is from our real works:

Gray Cast Iron:

Ultrasonic Speed: Less than 3700, meaning HT150, GG15, ASTM A48 No.

20, 25.

Ultrasonic Speed: 3700 to 4000, meaning HT200, GG20, ASTM A48 No.

30.

Ultrasonic Speed: higher than 4000, meaning HT250, GG25, ASTM A48

No. 35, 40, 45. or higher grades。

Ductile Cast Iron:

Ultrasonic Speed: Less than 5300, meaning unqualified ductile iron.

Ultrasonic Speed: 5300 to 5400, meaning tensile strength qualified,

but the rate of spheroidization is not good.

Ultrasonic Speed: 5400 to 5500, meaning barely qualified, but not

good.

Ultrasonic Speed: 5500 to 5600, meaning qualified and good.

Ultrasonic Speed: higher than 5600, meaning qualified and very good.

Cast Steel Castings:

Ultrasonic Speed: higher than 6000, meaning qualified and good.

If there is any porosity inside, the speed data will much higher

than normal data, for example, if there is porosity at the middle

position, then the data of speed will be doubled. In this way, we

could judge the depth of the defects. If there is no data at all,

then the defects will be extremely large. With all these experience,

we could use it to exam the inside defects of ductile iron, gray

iron and cast steel castings.

This device could help us to find out the castings with defects from

large quantity castings. Thank Dakota to make so good device for the

entire world.

Home |

More Articles |

|