Surface finish quality,

surface smoothness of cast iron and cast steel, sand castings made

in China

During price inquiry, many clients were

confused about the surface finish quality, surface smoothness of

cast iron and cast steel castings.

In this article, we will try to show some photos for casting surface

qualities, finish smoothness for lost wax investment castings, shell

molding, automatic molding, resin sand, and manual green sand

casting processes. So, you could understand how about the surface

finish quality our dandong foundry could produce.

This is the surface finish comparator from American Foundry Society.

Although we have not started to use this comparator, I hope to

introduce it just for your reference.

C-9 Micro-finish Comparator shows surface finishes from 20 to 900

RMS

Surface Finish Capabilities by Sand Casting

Processes

|

Casting Process |

Surface Smoothness in RMS |

|

Investment Casting |

50-125 |

|

Shell

Molding Casting |

75-150 |

|

Die

Casting |

90-200 |

|

Lost

Foam Casting |

125-175 |

|

Vacuum

Casting |

150-200 |

|

Nobake

(Resin) Sand |

150-600 |

|

Green

Sand Casting |

250-900 |

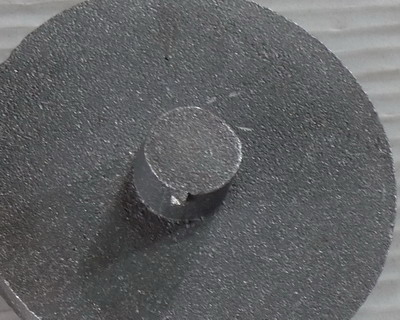

Surface quality and

smoothness of iron and steel castings

The following

photos are showing some gray iron, ductile iron and cast steel

castings made by our dandong foundry.

1. Manual

green sand, cast iron castings

traditional

casting process, the surface quality is difficult to control.

Sometimes, good, sometimes, very poor.

2. Resin sand, no-bake sand, cast iron castings

Comparatively good for large iron

castings, but not suitable for producing small iron castings because

of high production cost.

3. Automatic molding, green sand, cast iron castings

Surface quality is not the best,

but quality is very stable. We like it.

4. Shell molding castings, cast iron castings

It could produce better surface

quality than automatic molding, but sometimes not stable.

5. Lost wax investment castings, water glass, steel

castings

The surface quality is much better

than steel castings made by sand casting process.

6. Lost wax investment castings, silica sol, steel

castings

The surface quality is very good,

but its price is about 3 times of water glass investment casting

process. Very expensive.

7. Die casting, aluminum and zinc castings

The surface quality is perfect,

but this process is only suitable for making aluminum and zinc

castings, not suitable for producing iron and steel castings.

Home |

More Articles |