| |

Some clients were confused about the

mould costs, or pattern costs. We will briefly introduce the mould

pattern costs for cast iron sand castings, cast steel lost wax

investment castings, and metal patterns for die castings. For China

Foundries, the mould (pattern) cost is separated with the casting

prices. You must pay for the pattern cost in advance.

Function of Casting Patterns

No pattern, no castings. The patterns are the necessary tools for

casting production. Nobody can produce metal castings without any

patterns. You could call it as pattern cost, mould cost, tooling

cost, or initial cost.

Types of Casting Patterns

The patterns have different materials for different casting

processes. For example, the sand casting processes could use wooden

pattern, resin (plastic) pattern, aluminum pattern and iron pattern.

The lost wax investment casting process will use aluminum pattern or

iron patterns. The die casting process will use alloy steel

patterns.

Wooden pattern only can be used for

making some prototype or rough samples, can not be used for batch

production, because wooden patterns will get deformation after a

while.

Price Estimation of Casting Patterns

For the clients, it is too difficult to estimate the pattern cost,

since there are many factors could affect the pattern costs, and the

price ranges are very large, from hundreds dollars to tens of

thousands of dollars.

Herein, we just list the normal price range of different casting

processes and castings. Just for your reference.

|

Casting Process |

Very simple shape |

Normal complex shape |

Very complex shape |

|

Small size (USD) |

Large size (USD) |

Small size (USD) |

Large size (USD) |

Small size (USD) |

Large size

(USD) |

|

Manual green sand casting

(Resin Pattern) |

800 |

1200 |

1200 |

1600 |

- |

- |

|

Manual green sand casting

(Aluminum Pattern) |

1000 |

1500 |

1500 |

2500 |

3000 |

5000 |

|

Shell molding casting

(Iron Pattern) |

1000 |

1500 |

1500 |

2500 |

3000 |

5000 |

|

Automatic molding casting

(Iron Pattern) |

1500 |

2000 |

2000 |

3000 |

3500 |

5000 |

|

Resin sand casting process

(Resin Pattern) |

- |

1200 |

- |

1800 |

- |

- |

|

Resin sand casting process

(Aluminum Pattern) |

- |

2000 |

- |

3000 |

- |

5000 |

|

Lost wax investment casting

(Metal Pattern) |

1000 |

1800 |

1500 |

2500 |

2000 |

3000 |

|

Aluminum die casting

(Metal Pattern) |

5000 |

10000 |

8000 |

16000 |

13000 |

26000 |

Ownership of Patterns (Casting

Moulds)

Once clients paid for the patterns, then the client will own the

patterns. The Chinese foundries should not produce castings by these

patterns for any other clients. Otherwise, they will breach the

copyright of the client.

The client has the right to move the patterns to any other

manufacturers, foundries. The Chinese foundries should help the

moving.

Pattern Cost Refunding and Working Lifetime

If the foundries failed to make qualified samples or batch

production, they should refund the pattern cost to clients, or send

the patterns to other foundries.

The pattern mould cost is one-time cost, clients only need to pay

for the pattern for one time. The foundries and casting

manufacturers should maintain and repair the patterns by their own

cost. Of course, if the current patterns are not enough for large

quantity production, clients may require to make more sets of

pattern to speed up the production, then the clients should pay for

the more patterns.

For any question about pattern and mould costs, please contact our

Dandong Foundry.

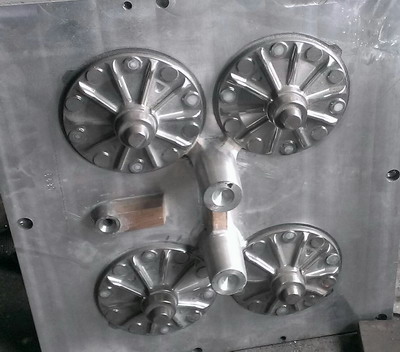

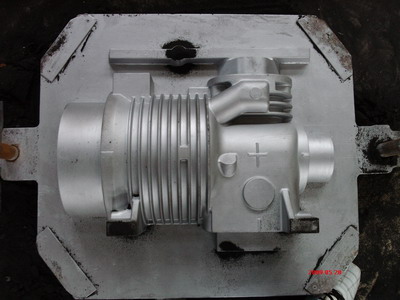

The followings are some photos for various patterns.

|

Iron Pattern for Automatic Molding |

Aluminum Pattern for Manual Green Sand |

|

Resin Pattern for Resin Sand |

Metal Pattern for Shell Molding |

|

Aluminum Pattern for Resin Sand |

Wooden Pattern for Sand Casting |

For the cast iron casting

prices, please refer to our "Cast

Iron Price Calculator".

For the cast steel casting prices,

please refer to our "Cast

Steel Price Calculator".

Home Page |

Casting Products |

Contact Us |

|