| |

Ductile iron castings

after high temperature annealing heat treatment

Our foundry performed high temperature

annealing heat treatment to ductile iron castings, in order to

remove massive free carbide, improve elongation (toughness), improve

welding property, remove inverse chill defects, reduce hardness, and

make the material more uniform.

Ductile iron fragile and solution:

Ductile iron is good because it has good elongation, so is very

tough, however, for some ductile iron castings with thin wall

thickness, low production temperature outside, there may be some problems with the material,

such as extra high hardness, fragile because of inverse chill

defects, and poor welding property. All these problems are difficult

to be solved by adjustment of casting process, so further heat

treatment will be necessary.

High temperature annealing heat treatment is a very good heat

treatment to solve these problems. We introduce a mature annealing

heat treatment process. 100 degree per hour to "A" Celsius

degree, then keep for "B" hours, then reduces temperature in the

furnace to "C" degree, and then pull the castings out of furnace.

(As for ABC, they are our technical data, so we are not convenient

to reveal them in this article.)

Heat treatment result:

After heat treatment, we found the mechanical properties and

metallographic structures have been improved significantly.

1. Elongation has been increased largely. Could be improved from 12%

to 20%, however, their tensile strength was not reduced as

theoretical estimation.

2. Inverse chill defects have been solved. Hardness has been reduced

largely.

3. Free carbide has been removed, so welding property has been

improved too.

In conclusion, material has become more tough and soft. All

properties have been improved significantly.

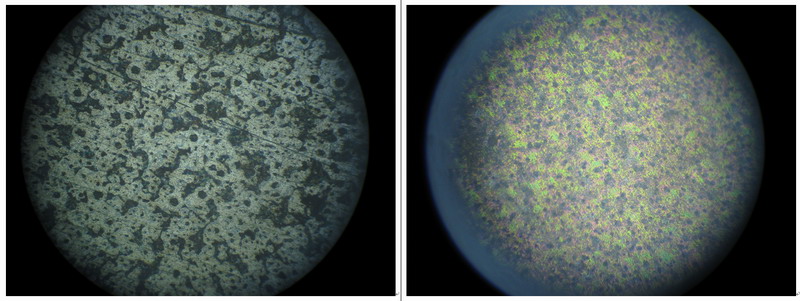

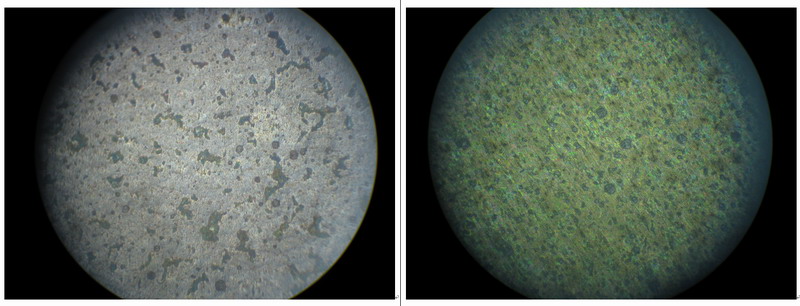

Metallographic photos:

The followings are some metallographic photos before and after heat

treatment. You could see the material has become very uniform after

heat treatment.

Because our Dandong foundry checked the inverse chilling areas on

the samples directly, not inspected the single specimen, so the

photos are not clear enough. If you want to learn more information,

please feel free to contact Galen Wang.

The above photos are showing the metallographic

structures of ductile iron 500-7 before and after annealing heat

treatment.

The above photos are showing the metallographic

structures of ductile iron 400 before and after annealing heat

treatment.

Home |

More Articles |

|