Green Sand Castings

Green sand casting process has been widely used

worldwide, and many types of metal castings were produced by this

process.

Green sand materials are very cheap and recyclable. They could be

used to produce small and middle sizes and weights castings. In

addition, this material is also suitable for both small amount and

large batch production. However, it is only suitable for making iron

castings, not for steel castings.

The followings are some green

sand castings produced by our foundry.

1. Valve Bodies

Butterfly valve

bodies normally have many models, but small annual demand.

So, they are suitable for green sand. Both GGG40 and GGG50 ductile

irons are suitable material grades for these products. Our foundry

are producing valve bodies from DN50 to DN500.

2. Tractor Parts

Tractor and auto parts have large annual

demand, and have high requirements to the dimensional tolerance and

material quality. Therefore, we produced these parts by automatic

molding line. We are produced tractors parts for John Deere and some

auto parts manufacturer in China.

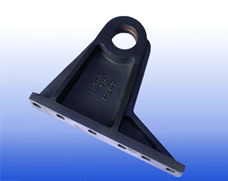

3. Brackets for trucks

Ductile iron brackets are very important casting parts for

engineering trucks, especially for hydraulic system. High percent of

spheroidization and less iron casting defects are the key aspects of

product quality. We are producing many cradle brackets for our

clients in Italy, Germany and UK.

4. Stove grates

Stove grates and burners do not have high requirements to

the material grade. Normally, GG15 and GG20 are very suitable.

However, the surface smoothness and less sand holes are very

important. Green sand could meet the middle requirements, and shell

molding could meet the high requirements, but which is more costly.

5. Boiler ash doors

Boiler parts normally required to add

some content of Cr to resist high temperature. Of course, surface

quality is also important for ash doors.

However, most of boiler parts do not have large annual demand, so

green sand castings are suitable for these products.

Home |

More Articles |