| |

Cast Iron and Cast Steel Castings Quality Control,

EX-work inspection,

Material, Visual, Defects and Dimensional Examination

As for cast iron and

cast steel parts, quality issues are always very important. The

following will elaborate our experience to the quality control,

ex-work inspection, material, visual, defects and dimensional

examination. Also we will introduce standard inspection reports and

certificates our Dandong foundry used.

Why the quality control is important

for metal castings?

The production for metal castings is a very complex process. There

are many processes involved, such as gating design, raw material

control, melting, pouring, sand control, molding, cleaning,

grinding, machining etc. Therefore, any mistakes and unstable

factors will cause some problems and defects. So, the quality

control is a very important mission for both producers and buyers.

Does the

buyer need to consider the quality control issues?

Some buyers may think the quality control is the responsibility of

foundries, but I think this is not correct.

The buyers will know the key quality points better than foundries,

so without the support and requirements from the buyers or final

clients, the foundries will misunderstand the quality requirements,

overlook the key points, or doing some useless inspection.

Therefore, the buyers should try the best to involve the quality

control as far as they could. Once if the compensation occurs, the

loss will be the money, market, reputation.

How did

the Chinese metal foundries control the casting quality?

As for the casting manufacturer, the metal foundries, they should

control the quality from the following aspects:

1. Raw material control, including pig iron purchasing, steel scrap,

alloy agents, sand materials and all other materials.

2. Sand molding control, this is inside control to molding workers.

3. Melting and pouring control, including the temperature and

pouring time.

4. Visual inspection to the surface qualities.

5. Dimensional examination to the before and after machining.

6. Chemical examination to the main chemical components, such as C,

Si, Mn, S, P etc.

7. Mechanical examination to the tensile strength, yield strength,

elongation, hardness etc.

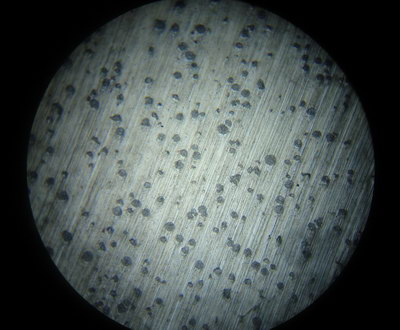

8. Metallographic examination to the micro-structure and nodular

rate etc.

9. Some special inspection, such as UT test, Impact test, hydraulic

pressure test, coating thickness etc.

What is

ex-work inspection for metal castings?

Before delivery, the metal foundry should focus on the following

inspection:

1. The material reports, needed and qualified?

2. The dimensional and visual reports, needed and qualified?

3. The main quality issues, problems, solved or not?

What is

material inspection report, certificate?

The following is a sample of material inspection report from Dandong

Foundry, you could see its main content including chemical

composition, and mechanical inspection results.

The

sample of material inspection report of pdf version.

What is

dimensional and visual inspection report, certificate?

The following is a sample of dimensional and visual report from

Dandong Foundry. We combined the dimensional and visual inspection

results in one report, which will be better for both inspectors and

the buyers.

The sample of dimensional and visual inspection result of pdf

version.

How to

inspect the main quality issues and problems?

We made one document for each casting part. This document will

elaborate the main quality problems occurred before, and all key

quality points. This document will be updated step by step with the

improvement of the casting parts. So, before delivery, the inspector

will see this document, and will check if these problems have been

solved.

How to

inspect the casting defects?

The castings defects will include the surface defects and inside

defects. There are various defects for cast iron and cast steel

castings, for the photos of defects, please refer to our article “metal

casting defects”.

Therefore, there are many different inspection methods for the

different defects. Most surface defects could be found by visual

inspection. As for the inside defects, the ultrasonic inspection is

effective. Other defects inspections include liquid penetration,

X-ray inspector, magnetic powder inspection etc.

There are also some destructive inspections when we make samples.

Although this method will scrap the castings, the result is more

accurate and evident.

Our Dandong Foundry is also using USA

Dakota Ultrasonic Velocity Inspector to inspect the material quality

by batches and the inside defects.

Home |

More Articles |

|