| |

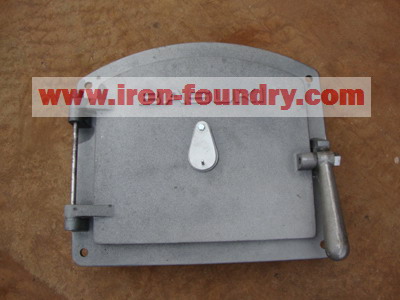

Small Cast Door

Small cast door is

the small doors made by cast iron, which

was also called as small casting door,

stove casting door or cast iron door.

There are many types of cast doors

according to the application. Such as

the cast doors used on the boilers, they

are called ash door, the cast doors used

on the furnaces, fireplaces and stoves.

You could call them as stove door. Small

cast door means their size is small,

usually from dozens of millimeter to

hundreds of millimeter.

The materials were used for small cast

doors include grey iron, ductile iron,

alloy cast iron. Most of material is

grey cast iron

ASTM A48 Class 30, Class 20

,or gray iron

DIN EN1561 EN-GJL-200,

EN-GJL-150, or grey iron FC150, FC200.

In order to improve its fire-resistant

property, usually require to add some

content of Chrome (Cr) alloy. 1% Cr

should be good for this purpose.

As for the small cast door,

Dandong Foundry usually made

the larger cast doors by green sand

floor molding process, made the smaller

cast door by resin sand shell molding

process. Usually, the automatic molding

line is not suitable for small cast

doors since the hot cast doors need to

stay in the sand molds for over one

night to avoid the deformation.

Of course, for cast doors, the surface

quality must be very good. In order to

meet the surface quality, Dandong

Foundry use the fine sands and precoated

resin sands as the molding materials.

As for buyers, the surface quality will

be the first inspection point, then the

flatness will be also very important.

Although material is not very important,

the suppliers should meet the standard

for materials, otherwise, the cast doors

are easily crashed.

Usually, most of cast doors do not need

polish. If you need, you

should denoted them on the drawings or

in your inquiry, and the coating

requirements are also important to the

cast doors, such as painting,

galvanizing, anti-rust methods.

There are many iron foundries in China

could produce cast iron doors, however,

only few of them could make them very

well. The most difficulty for producing

them is keeping the good surface

quality.

Home |

More Articles |

|