| |

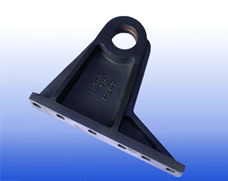

S.G. Iron Castings

SG iron is called as spheroidal graphite

cast iron, or also called as ductile

iron or nodular iron.

This iron material is very common in China and worldwide, because of

its superior physical properties and mature production processes.

SG iron is suitable for producing many types of castings, such as

the iron parts for agricultural and engineering machinery, pump and

valve bodies, pipe fittings, manhole covers etc. The sg iron is

about taken 70% production output for all

iron castings worldwide.

High tensile strength and good ductility are the main characters of

s.g. cast iron. As for sg iron 900, its tensile strength can exceed

827 Mpa, yield strength can exceed 621 Mpa. As for sg iron 400, its

elongation can exceed 18%. The most common material grades are sg

iron 400, 450 and 500 because of their excellent comprehensive

physical properties.

The hardness range of sg iron castings is as following:

400/18, 400-15: BHN 130-180

450/10: BHN 160-210

500/7: BHN 170-230

600/3: BHN 190-270

700/2: BHN 225-305

800/2: BHN 245-335

900/2: BHN 280-360

The chemical composition has the following range:

C: 2.7-3.8%, Si: 0.5-3.8%, Mn: 0.2-0.7%, S ≤0.02, P ≤0.1, Cr ≤0.15.

The above chemical composition is just from foundry experience,

which can not be taken as the quality standard of inspecting sg iron

products.

As for sg iron pipe, it could be produced by continuous casting

process. But as for the most of sg iron castings,

sand casting process

is most suitable production method. Green sand, resin sand and shell

molding are the common molding process in China.

Home |

More Articles |

|