The Surface Quality of Iron and Steel Castings

Surface smoothness and defectives are

important quality aspects of iron and

steel castings. Some steel casting purchasers may wonder

why the surface quality of steel castings is worse than iron

castings, such as lower surface smoothness, more surface sand holes,

air holes, and sand residuals. Herein, we hope to explain this

issue.

We can try to make a comparison list for the surface quality of all

normal iron and steel casting processes from best to worst.

1. Best surface – steel castings produced by

lost wax investment casting

process. The lost wax silica sol or water glass materials

will make the surface quality and smoothness of steel castings very

good. No sand casting

defects.

Steel Casting made by Lost Wax Investment Casting Process

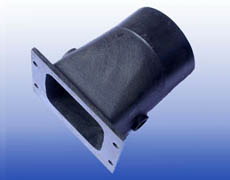

2. Very good surface –

iron castings produced by hot

shell molding process. Hot shell and

core molding process will use the yellow pre-coated resin

sand as the molding material, which has very smooth surface and no

sand residuals.

Iron Casting made by Shell Molding Process

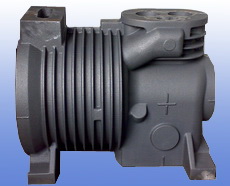

3. Good surface – iron castings

produced by molding machines or

automatic molding line. Molding machine and automatic

molding lines could cause the high and even molding pressure, which

is very helpful to the surface smoothness and improve the defects.

Iron Casting made by Automatic Molding Line

4. Good surface – iron castings

produced by very fine green sand. This kind of sand is very small

and uniform, which is very good to the surface smoothness, but not

every iron foundry use this

sand since it is only suitable for producing small iron castings.

Iron Casting made by Fine Green Sand

5. Normal surface – iron castings

produced by resin sand casting

process. Furan resin sand is hard sand, so it has better

surface quality, however, this process normally used for making

large iron castings, so sometimes, the surface defects are

inevitable. If your products are large, then resin sand will be the

best choice.

Large Iron Casting made by Resin Sand

6. Normal surface – steel castings

produced by lost foam

casting process. This process is good for surface quality,

as for the large steel castings, this process is the best choice,

however, not many steel foundries

in China can handle this process very well.

7. Normal surface – iron castings

produced by normal green sand of hand molding. I do not need to say

too much about this process, which is very common.

Iron Casting made by Normal Green Sand

8. Bad surface – steel castings

produced by sand casting process

of hand molding. Since steel castings need better air permeability

to molding materials, so the size of sand used for steel castings

will be larger than for iron castings, which is the main reason for

worse surface quality.

Steel Casting made by Sand Casting Process

Herein, we just talk the difference of each

casting process, but on the other hand, the quality of foundry sand,

the pouring process and operation of workers will also affect the

surface quality of castings.

Home |

More Articles |