Dandong Foundry is making a brief introduction to the production process of custom cast steel, the types of custom cast steel castings, and OEM manufacturer in China.

Production process of making custom cast steel castings

1. Making wooden, resin, aluminum or steel patterns according to the samples or drawings. The patterns are necessary tools for making custom cast steel parts.

2. Making sand moulds or wax moulds by patterns according to the different casing methods. The moulds were made by patterns. Many customers were confused about moulds and patterns. The patterns are tools, one set of patterns could make many moulds, but one mould can only be used for making one piece or several pieces of casings.

3. Melting steel materials, then pouring the liquid steel into the moulds, then get rough steel castings.

4. Sand blasting the steel castings, then grinding off the parting lines, getting clean rough castings.

5. Machining will be the following works if needed.

Types of custom cast steel castings

For the unit weight from dozens to hundreds kilograms, sand casting is a proper casting process, but the surface quality will not be good.

For the unit weight up to dozens kilograms, lost wax investment casting process will be a good choice. In China, this process also divided into two types, water glass and silica sol investment casting process. Water glass is much cheaper, but this casting process is on the way out because of pollution control in China. Silica sol is good, but about triple expensive than water glass.

Shell molding process is a mature casting process for cast steel overseas, but it is a new one in China, because the resin sand can not stand high temperature of liquid steel very well, so this process has not been widely used for cast steel, although it has been used well for making cast iron castings.

OEM manufacturer of steel castings in China

There are many steel casting OEM manufacturers in the past, especially in South of China, we produced many tons of steel castings for exporting overseas, however, in the recent years, especially in 2017, because of the pollution control in China, many small steel foundries have been closed.

The cast steel prices have increased significantly too, because of the pollution control, increased material costs and manpower costs. The casting prices may be higher in 2018.

Custom cast steel casting products

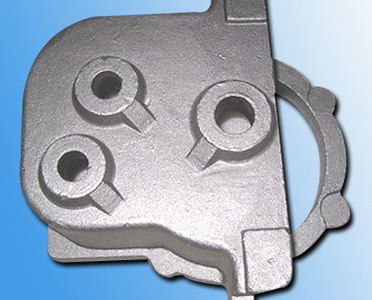

The followings are some cast steel castings made by sand casting process:

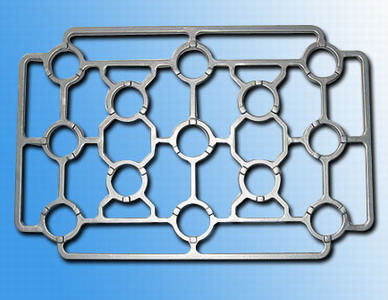

The followings are some cast steel castings made by lost wax investment casting process of water glass:

The followings are some cast steel castings made by lost wax investment casting process of silica sol:

|