What is the difference of gray iron, ductile iron and carbon steel? You may need to learn about these information when you choose the right material for your casting products.

1. What is Cast Iron?

Cast iron means the metal with carbon content upper than 2%. It could be divided into gray cast iron and ductile iron (also called as S.G. Iron).

2. What is Carbon Steel?

Carbon steel means the metal with carbon content lower than 2%. If it needs more alloy content, such as Cr, Mo, Ni or Cu, then it will become into alloy steel.

3. The main difference of Cast Iron and Carbon Steel.

a) Their carbon content is the main difference.

b) Their material microstructure is different.

c) Their physical properties are different.

4. Comparing their microstructure.

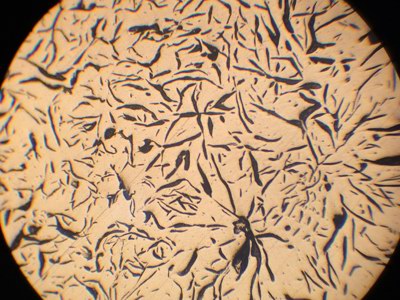

The following is the metallograph for the gray cast iron. You can see the obvious flake graphite. The black graphite is flake shape, when you see them on cross section, they look like strip.

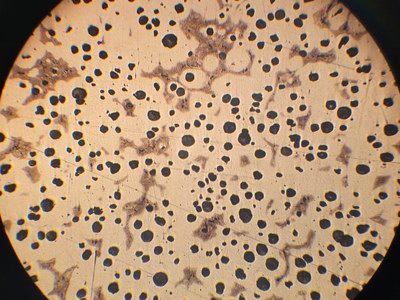

The following is the metallograph for ductile iron, you can see many black spheroidal graphite. The speroidal graphite has the smaller breaking stress than flake graphite, so make the ductile iron to be better.

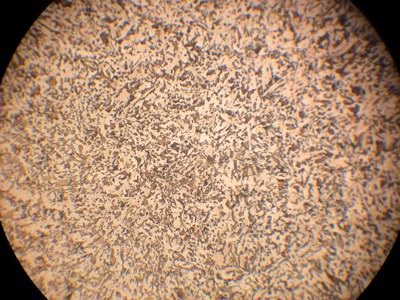

The following is the metallograph for carbon steel. You can see there are many small graphite. Although they are not speroidal, they are very small and special structure, so form better mechanical properties.

Their different graphite structures cause big difference to their physical properties.

5. Comparing their physical properties.

Gray cast iron has good casting properties, good vibration damping, good wear resistance, good machinability and low notch sensitivity. However, its tensile strength and elongation are very low, so grey cast iron is suitable for producing some metal parts with low mechanical requirements.

Ductile iron has higher strength, better ductility, heat-resistance and toughness than grey iron, so it has a wider application, in some cases, ductile iron can replace carbon steel.

Carbon steel has higher strength, very high ductility, and toughness, even better than ductile iron. The smelting process is relatively simple. It has good pressure processing performance, good cutting performance and good mechanical properties. After proper heat treatment, they could meet many industrial production requirements.

Testing Specimen for Mechanical Inspection

6. Comparing their production prices.

The gray iron is the cheapest, the ductile iron has higher price than gray iron, the carbon steel may have the similar price as the ductile iron if using sand casing process, but may have much higher prices if using investment casting process.

If you want to learn about their approximate prices, please refer to our cast iron price per lb and kg, and cast steel price per lb and kg.

If you want to calculate their accurate prices, welcome to use our free price tools, cast iron price calculator, and cast steel price calculator.

7. Comparing their production methods in China.

Gray iron and ductile iron are normally produced by sand casting process, including green sand machine molding, shell molding (hot shell and core molding) and furan resin sand casting. Also, they could be made by lost foam casting process too. Because of various casting methods, our Dandong foundry could produce iron castings by size from several centimeters up to 2 meters, the unit weight from 0.5kg to 1300kg, the production rate could reach 30 tons each day.

automatic molding sand casting process

Carbon steel could be produced by sand casting and lost wax investment casting process. Sand casting process could produce very large and heavy steel castings, but the surface quality is poor. Lost wax investment casting process could produce very small and complex castings, but its prices are much higher than sand casting process. Our Dandong foundry is using shell molding process to produce carbon steel casting, so the surface quality is better and price is lower.

lost wax investment casting process

8. Conclusion after comparison

Some suggestions for you! If your casting products do not have high mechanical requirements, then gray cast iron is the best choice. If ductile iron could meet your mechanical requirement, then choose ductile iron. If all cast irons can not meet your requirement, then carbon steel or ally steel will be the last choice.

|