| |

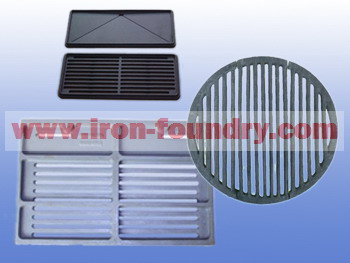

Cast Iron Fire Grate

In China, you could find many types of

cast iron fire grates, such as round fire grate, square fire grate,

camping fire grate etc.

According to the application, the cast iron fire grates could be

divided into gas fire grate, coal fire grate and wood stove fire

grate.

The material of fire grate is usually

grey iron, or called as

gray iron. Normally, it is not necessary to produce the fire

grate by nodular iron (ductile

iron), since grey cast iron is cheaper. Some clients may

require to add some Cr (chrome), Ni and Mo alloys to improve its

anti-fire property. According to the experience of

Dandong Foundry in China, the Cr is

useful for the high temperature fire grate, but Ni and Mo are not

necessary, but it will depends on the different applications.

As for the casting process for fire grates, for small grates, we

suggest to use the green sand floor

molding process, which is the most cheap and suitable for

the fire grates, since this process can keep the liquid hot iron

into the sand molds for one night, which could keep the good

flatness for the fire grates.

For the large fire grates, which are very seldom, you could consider

to use the resin sand casting

process.

For the large quantity fire grates, such as over 30 thousands of

pieces each year, you could try to use the

automatic molding line

because of its high production rate. However, not all grates could

be produced by automatic molding lines since the short time cooling

and drastic vibration cleaning may could the deformation to the fire

grates.

As a buyer for the cast iron fire grate, what are the main issues

for your purchasing process in China?

Firstly, of course, find a good iron foundry who has the experience

in producing fire grates and can offer a reasonable price.

Secondly, checking the material to the sample and batch products. In

order to reduce the material costs, some small foundries may use the

large quantity of scarp iron as the main material, therefore, their

grates could not meet the material requirements, mainly means the

tensile strength requirement. Unqualified material will cause the

fire grates very fragile.

Thirdly, check the dimensions, especially the flatness, and the

surface quality. Since most of cast iron fire grates are anti-rust

painted, therefore, the repairing by the cast iron repairing

adhesive or welding, should be allowable. However, if the clients

need further

porcelain enamel coating treatment. Then, any types of

repairing will be forbidden since the repairing may affect the

failure of the porcelain treatment.

Home |

More Articles |

|