| |

What is Machining Tolerances?

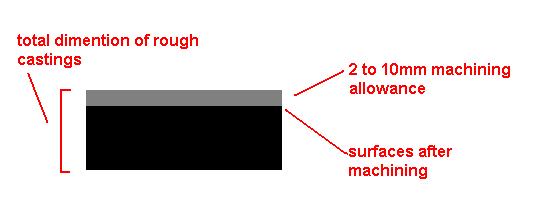

Machining tolerances

are meaning how many dimensional allowances the casting producers

need to leave for the machining works. Please see the following

diagram. On the surfaces after machining, the rough casting

producers need to leave 2 to 10 mm machining allowance for the

machining.

Why we need to

consider the machining allowances?

Some buyers may think the allowances should be considered by rough

casting producers, and it has no relations with buyers. This is not

total correct for the following some reasons.

1. If the casting producers just supply the rough castings, then

buyers have designated other

machining workshops to machine for them. Then, the buyers

or machining workshops have to tell the rough casting producers

about the machining allowances, in case of the insufficient

allowance for the machining.

2. Even the casting

foundry in charge of machining in-house. If the buyers could provide

more information about the machining allowances, then it will be

more helpful for casting foundries

to reduce the sampling time, and reduce more wastage. If the cast

foundries use metal

patterns, then the allowance should be considered carefully

since the modification to the metal patterns will be more difficult.

3. The metal

foundries consider their

rough casting costs based on the real rough weights of

castings, which means if the machining allowances are too large,

then their production costs will be increased, and so their prices

will be higher. If the buyers could give correct information to the

allowances, then it will be very helpful to reduce the

casting prices.

How to consider the machining allowances?

Most machining allowances should be considered by the experiences.

Normally, as for the automatic

molding line, molding machines and

shell molding processes,

then 2 to 3mm will be suitable. As for the

manual green sand and

resin sand casting process,

then 3mm to 5mm will be proper. However, as for the

large castings, or for

large surfaces, then the machining allowance should be 5mm to 10mm.

This is because large castings have larger dimensional tolerances,

and more surface casting

defects, so larger machining allowance will be necessary to

remove defects and avoid allowance insufficiency.

Of course, the metal foundries should have more experiences than

buyers, but at least, the buyers should understand why the suppliers

always care about the rough casting weights, and machined weights.

Home |

More Articles |

|