| |

Green sand, resin sand, shell molding, iron and steel castings

produced by metal foundries, casting suppliers and exporters in China

As for the most of

metal foundries

and casting suppliers in China, the green sand, resin sand and shell

molding are the normal production processes, the cast iron and cast

steel are the normal casting materials.

1. Green Sand Casting

Most of sand castings were

produced by green sand.

It is mainly because its low cost, simple production equipments and

flexible process. Currently, the green sand rough

casting prices are about

1.24 USD/kg for grey iron, 1.35 USD/kg for ductile iron.

2. Resin Sand Casting

Resin sand is a type of

Furan resin self-hardening sand. After heating, the sand will become

solid, so it could produce middle and large castings with complex

structure and high accuracy. However, the Furan resin material is

costly, so cause high prices. Currently, the resin sand rough

castings are about 1.38 USD/kg for

grey iron, 1.49 USD/kg for

ductile iron.

3. Shell Molding Casting

Shell molding process is

also called as hot shell and core molding, which uses yellow

phenolic resin as the sand binder. After baking, the resin sand

molds become very hard and smooth, so the castings made by this mold

will have very good surface quality and high dimensional tolerance.

This process is suitable to produce small and middle sizes iron

castings with high quality requirements and complex structures, or

with thin wall thickness. But this resin sand can not be recyclable,

so it will be costly. Currently, the rough casting prices by this

process is 1.47 USD/kg for gray iron, and 1.58 USD/kg for ductile

iron.

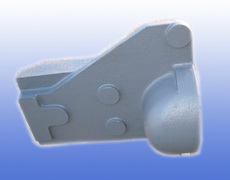

4. Cast Iron Products

Metal castings are the base of industries, so there are many types

of metal parts were made by casting process.

Cast iron products

include metal parts for tractors, trucks, various machinery,

automotive, pump, valve, pipe fitting, drainage system, stove,

boilers, boats and many more areas.

5. Cast Steel Products

Steel castings also have

very wide demand. Alloy steel castings have special properties such

as heat-resistant, anti-corrosion, wear resistant, according to

their added alloy such as Ni, Cr, Mo, Cu etc. In China, most cast

steel products were produced by sand casting, lost wax casting and

lost foam casting process, however, shell molding process is seldom

used for now in China.

6. Metal Foundry, Casting Supplier,

Exporters in China

There are many metal casting

suppliers in China. Some are metal foundries, some are

machining workshops that have their casting sub-suppliers, some are

trading companies. As for middle and large suppliers, they have

their own export license, so they could enjoy export tax rebates,

which means they could offer lower prices to buyers.

Home |

More Articles |

|