| |

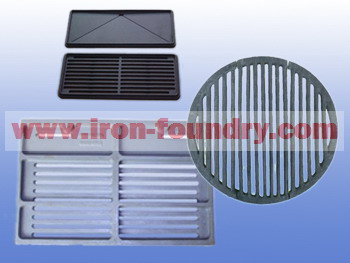

Cast Iron Gas Stove Grates

Cast iron grates are an important

component for gas stoves, our foundry has produced some stove grates

for our clients in USA and Germany for years.

Cast Iron Material

The material is normally grey iron ASTM

A48 Class 20, Class 25, and Class 30. In Germany, it will be

GG15 and GG20 grades. Gray cast iron has better cast ability, and

better resistance to deformation of heating, most important, cheaper

cast iron prices.

Casting Production Process

Most of gas stove grates were made by

shell molding process, also known as pre-coated resin

sand casting process. This process could meet better surface

quality, less surface sand casting defects, and less deformation.

However, the disadvantage will be higher production costs than green

sand.

Metal Pattern Costs and Casting Prices

The metal pattern costs for gas stove grates will be higher than

normal iron castings, it is

because it will cause more machining work time. The price of

castings will be higher too, because it will use more resin sands,

and more work time for grinding and cleaning. Most of stove grates

have the flatness and straightness requirements under 1.0 mm or

under 1.5 mm, so the iron foundry inspectors need to inspect them

one by one, and need to rectify the over-sized casting parts, all of

these works cause the high prices.

Besides of cast iron gas stove grates, Dandong Foundry in China can

also produce many types of cast iron coal stove grates, and wood

stove grates.

Home Page |

Casting Products |

Contact Us |

|