| |

Shell Molding Process VS Green Sand Casting

As for some complex or thin wall thickness

castings, we often suggested our customers to use shell molding

casting process, instead of green sand casting process. However,

some customers were confused about their difference, advantages and

disadvantages. Herein, let us make a brief comparison.

The main

differences of shell molding process vs. green sand casting

1. Different sand materials

Green sand casting process uses wet clay as the bonded material, so

its material cost is very low. However, shell molding process uses

phenolic resin as the bonded material, which will be more costly.

Green sand is black, and pre-coated resin sand is yellow.

green clay sand

pre-coated resin sand

2. Different production costs

Shell molding process needs to use expensive pre-coated resin sand,

and needs to make sand molds by molding machines.

Therefore, its production cost will be higher than green sand

casting process. Normally, the iron castings made by shell molding

process will cause higher production costs 0.15 to 0.30 USD/kg.

3. Different tooling costs

Shell molding process needs to use metal patterns, because the

pre-coated resin sand needs to be baked at very high temperature in

molding machines. So, its tooling cost is comparatively higher.

Green sand casting process could use cheaper plastic patterns (also

called as epoxy resin patterns), and aluminum patterns. When making

samples, even wooden patterns could be used.

epoxy resin pattern

metal patterns for shell molding

The advantages and

disadvantages of shell molding process

1. Good surface quality and less casting defects

Shell molding castings have very high surface quality, good finish

smoothness, and less sand casting defects, such as sand inclusion,

air holes and sand drop.

green sand casting surface

shell molding casting surface

2. Higher dimensional tolerance and

less straightness deformation

Because the pre-coated resin sand molds are a type of hard molds, so

the shell molding castings have very high dimensional tolerance.

Moreover, the iron castings could be cooled in the sand molds for

long time, so they will have less deformation of straightness and

flatness.

3. Suitable for complex structures and thin wall thickness

The strength of shell molds is higher than other sand molds, so they

could be used to produce the iron castings with complex inside and

outside structures, such as stove gas burners, manifolds etc.

Moreover, they could control the wall thickness very thin to 5.0 mm,

and make the wall thickness very uniform.

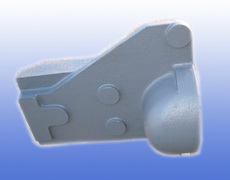

shell molding castings

4. High casting prices and tooling

costs

Of course, the disadvantages of shell molding process are high

casting prices, and tooling (metal pattern) costs.

5. Have limitation to casting weights and sizes

Because of the size limitation of shell and core molding machines,

this process is not suitable to produce very heavy and large

castings, such as over 500 mm long, or 30 kg weight.

The advantages and

disadvantages of green sand casting

1. Low casting prices and tooling costs

The largest advantage of green sand casting process is lower casting

prices and tooling costs. Especially, for large castings, the saving

for tooling costs will be very considerable.

2. Suitable for larger or heavier castings

The restriction to casting weight and size is comparatively few. So,

green sand casting process could produce small castings less than

0.5 kg/pc, and can produce large castings heavier than 300 kg/pc

too. The casting sizes could be from 20 mm to 2 meters.

green sand castings

3. Worse surface quality and casting

defects

Its disadvantages are also very obvious. The surface quality is not

good, and sand casting defects will be comparatively more than other

casting processes.

However, it does not mean their surface quality can not be

acceptable. If the iron foundries use very fine sand, or use

automatic molding equipments, their surface quality will be good

enough for most of requirements.

4. Low dimensional tolerance

If the iron foundries use manual molding green sand, then the

casting dimensional tolerance will be lower than shell molding

process. However, if they use automatic molding machines with green

sand, the tolerance will be much better.

Summary

Both green sand casting process and shell molding process have been

widely used worldwide, so their own advantages are undeniable.

Normally, the iron foundries will suggest to use some suitable

casting process according to the casting weight, size, structure and

requirements. So, the customers should learn about their differences

to costs and casting quality.

Home |

More Articles |

|