| |

What Can Affect the Quality of Iron Castings?

The quality of

iron castings is

very important to the development of an

iron foundry, and there are many elements that influence

the quality of iron castings, such as design process, casting

process, the quality of raw materials and technological operation.

1. Design process of the iron castings

During the design process, in addition to

determine the shape and size of iron castings based on the working

conditions and the property of metal materials, we should also

consider the rationality from the perspective of casting alloy and

characteristics of iron castings, that is obvious size effect and

solidification, shrinkage,

stress and other issues in order to avoid or reduce the casting

composition segregation, deformation, cracks and other

metal casting defects.

2. Reasonable casting process

The reasonable

casting process is

very important, that is according to the casting structure, weight

and size, characteristics of casting alloy and working conditions,

we should choose a suitable parting and molding, core-making method

to design casting bars, iron chill, and riser and gating systems.

3. Quality of raw materials

The third is the quality of raw materials

used in metal casting. Metal

charge, refractory material, fuel, flux, modifier, foundry sand,

molding sand binder, paint and other materials, if any of them is

not up to standard in quality, air hole, pinhole, slag inclusion,

adhering sand and other casting defects will appear, which will

affect the appearance and internal quality of castings, even cause

casting scrap.

4. Technological operation

The fourth element is the technological

operation. A reasonable operation process should be made to develop

rules to enhance the technical level of workers, and make sure the

engineering procedure to be implemented correctly.

In order to control the quality of iron castings, the inspection is

very necessary and important.

First, we should formulate control and inspection codes and

engineering factors about the raw materials, auxiliary materials

even each specific product process. Each process is strictly

controlled and inspected according to inspection codes and technical

conditions.

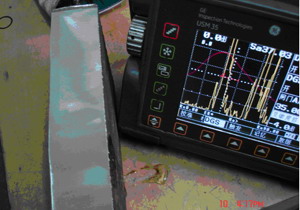

Then, we should inspect the finished castings. We can use reasonable

testing methods and allocate appropriate testing staff. About the

presentation quality of castings, we can use comparison specimens to

judge surface roughness; the hair line on surface can be examined by

staining method and magnetic particle method. About the internal

quality, we can use frequency, ultrasound, whirlpool, x ray and y

ray and other methods to test and judge.

Ultrasonic inspection device

Magnaflux inspection device

X ray testing device

Home |

More Articles |

|