| |

Inspection Methods to Ductile Iron Castings

Normal casting defects of ductile iron

include some macro-defects, such as air holes, sand inclusion, slag

inclusion, shrinkage

or shrinkage cavity, and some micro-defects, such as unqualified

nodularity rate and too large grain size, etc.

The inspection methods to ductile

iron castings include visual inspection, magnetic powder

test and ultrasonic test.

1. Visual Inspection

Visual inspection is the most heavy

works, they need lots of grinding works accompanied. Normally, the

visual inspection require to meet the following requirements:

a) No cracks, no welding treatment, no

sand or slag inclusion.

b) No obvious sand holes or air holes. As for allowable sizes and

amount for the air and sand holes, you could refer to the other

articles in Dandong Foundry Blog. As

for the different castings, there are different requirements.

c) No cold flake or mismatch defects.

d) No machining scratch or impression.

During visual inspection, it is hard to

distinguish the air holes and sand holes. Air holes normally have

smooth inside surfaces, and have regular shapes, but sand holes have

irregular shapes and have dirt or sand residues inside. As for the

air holes, since they are shallow, the inspector could measure their

sizes, and check if they are allowable, but for the sand residues,

most of them will cause deeper damages to the castings, so they

should be grinded or repaired before acceptance.

Moreover, the inspector should check the sand blasting. The

inadequate sand blasting will cause the rough surface quality, or

even leave the oxide skin. These situation should be sand blasted

again or be grinded further.

2. Magnetic Particle

(Powder) Inspection

Magnetic particle inspection is a kind

of

NDT testing. The florescent magnetic particle testing is

suitable for ductile iron castings. According to our experience,

both the water base magnetic flaw detection ink and dry magnetic

particle are suitable for inspection to ductile iron. Since the

surface smoothness has large effects to the inspection results, so

you could try to grind the surfaces to improve the inspection

sensitivity. Normally, the casting head areas easily have defects.

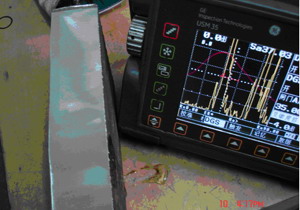

2. Ultrasonic Testing

Ultrasonic testing is also an inspection

method to ductile iron castings. It could inspect not only air holes

and sand holes, but also inspect the slag inclusion, cracks and

other material defects. However, comparing with the cast steel,

forged or welding parts, ultrasonic testing to ductile iron castings

has high difficulties, and the results need careful and skillful

identification. It is because ductile iron has more complex inside

structures. Some structures may cause the wrong judgments, and

moreover, the surface quality has some effects to accuracy of

inspection results.

Home |

More Articles |

|