Grey Iron vs. Nodular Iron

Many people will wonder the differences

between grey iron and nodular iron, this article is intended to

introduce the grey iron and nodular iron in microstructure, physical

properties and chemical composition.

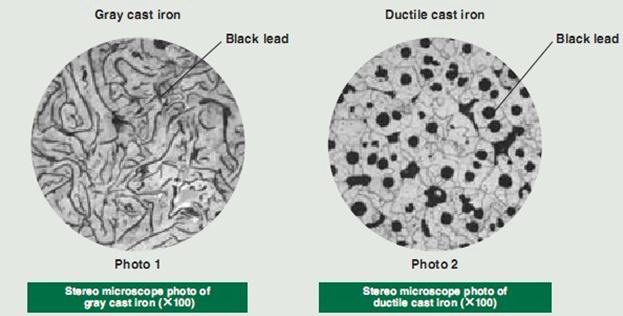

1. Microstructure

The key feature of grey iron is that it includes flakes of graphite

which develop during the cooling process. These graphite flakes give

grey iron a distinctive gray color when it is fractured, and they

are also involved in many of the physical properties of this iron

alloy.

The microstructure of nodular iron is the

discrete form of the graphite nodules. Nodular iron is created by an

alloying process, which converts the crack-promoting graphite flakes

of gray iron into nodules. With this micro-structural

transformation, the metal acquires superior ductility and elongation

characteristics.

2. Physical Property

Compared with grey iron, nodular iron has an absolute advantage in

intensity. The max tensile strength of nodular iron is 90k psi,

while the max tensile strength of grey iron is only 35k psi.

Nodular Irons are generally superior to

grey irons, regarding their yield strength. The max yield strength

of ductile iron is 40k psi; Grey iron is not very malleable or

strong, it fractures easily.

Nodular iron is more flexible and elastic

than other cast irons. Nodular iron has higher strengths, greater

elongation and better resistance to impact than grey iron.

The nodular iron family offers the design

engineer a unique combination of strength, wear and fatigue

resistance and toughness as well as excellent ductility

characteristics. In all its grades, nodular iron exhibits mechanical

properties that make it an ideal materials for mechanical and

automotive parts.

Gray iron is the most versatile of all foundry metals. With the

exception of wrought steel, grey iron is the most widely used metal

for engineering purposes. Grey iron is an extremely inexpensive

metallic material and is readily available in large quantities at

almost any foundry.

3. Chemical Composition

|

Chemical composition

|

Cast Iron Material |

|

Grey iron (%) |

Nodular iron (%) |

|

C |

2.9~3.5 |

3.5~3.8 |

|

Si |

1.4~2.1 |

2.0~3.2 |

|

Mn |

0.6~1.0 |

<0.5 |

|

P |

0.1~0.5 |

<0.08 |

|

S |

0.1~0.12 |

<0.025 |

|

Mg |

|

0.03~0.06 |

|

RE |

|

|

The different chemical composition of grey

iron and nodular iron directly determines their different

properties. After reading the above analysis, we hope your can get a

better understanding about grey iron and nodular iron.

Home |

More Articles |