Cast Metal

Metal castings are the base of industry.

There are many types of cast metal methods, patterns and casting

parts.

Cast Metal Methods

1. Manual Green Sand Molding Method

This casting method is the most common and cheapest in China and

worldwide. Moreover, it can produce iron castings from dozens of

grams to half of tons. In addition, it is suitable for small batch

production and middle volume production.

However, the production rate is very normal. The metal castings have

many defects, and do not have high dimensional tolerance.

2. Automatic Molding Method

This method is also using green sand as the main molding material,

however, different with manual green sand casting method, it uses

automatic molding equipments, which is suitable for large batch

production, better dimensional tolerance, less metal casting

defects.

But it has limitation to the casting sizes and annual demand. It is

not suitable to produce too small and too large castings, and not

suitable to small orders.

3. Resin Sand Molding Method

Furan resin sand molds are a type of

hard molds, so it can be used to produce large iron castings up to 2

tons. Moreover, it can meet higher dimensional tolerance and less

casting defects.

However, its production cost is high, and production rate is low.

But there are many iron foundries in China using this method to

produce large and complex cast metals.

4. Shell Molding Method

This method is also using a type of

resin hard mold, so it can use to produce small and complex iron

castings, but its casting prices are higher than furan resin sand.

5. Lost Wax Investment Molding Method

This cast metal method normally produces

steel castings in China. Since it uses wax, water glass or silica

sol as the main materials, so its dimensional tolerance, surface

quality and casting defects are very good.

This method is a type of precision casting process, and its metal

casting prices are very high.

6. Die Casting Method

This method is normally used for producing aluminum and zinc

castings. There is no sand casting defects, and its casting quality

and cast metal density are very good because some press involved .

The production rate is also good, just production costs are not low.

7. Permanent Mold Casting Method

This method is also normally used to produce aluminum and zinc

castings. Different with die casting, this method could produce

larger castings.

8. Continuous Molding Method

This method is for producing metal sheet, bars or tubes. Its casting

quality is very good, but it is not flexible, only can be used to

produce simple and continuous castings.

Cast

Metal Patterns

In order to make metal castings, the patterns are necessary. There

are mainly several types of patterns.

1. Wooden Pattern

Wooden patterns can be used for manual green sand casing method,

steel sand castings, and resin sand casting methods.

These patterns are cheap, however, its strength is low, and easily

deformed and damaged, so normally only used to make samples. They

are not suitable for batch production.

2. Resin Pattern

The pattern is also called as plastic pattern, so fully called as

fiber glass reinforced epoxy resin pattern.

The resin patterns have long life time, and much more cheaper than

metal patterns, however, its dimensions and surface quality will not

be as good as metal patterns, and they can not be used to produce

complex metal castings.

3. Metal Patterns

Metal patterns include aluminum patterns, iron patterns and alloy

steel patterns. Most cast metal patterns were made directly by 3D

drawings and CNC centers, so they have very high dimensions,

complexity and surface quality.

Permanent Mold Casting Pattern

This is the steel patterns for permanent

mold casting method. The alloy steel has higher melting point than

aluminum and zinc metals, so it could be used to produce aluminum

and zinc castings.

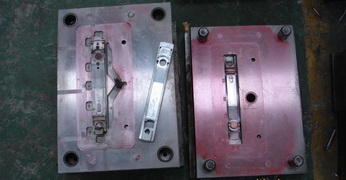

Die Casting Pattern

This is the metal patterns for die casting

method.

Lost Foam Casting Pattern

This is the metal patterns for lost foam

casting method. The foundries use these metal patterns to make many

foam molds, then use the foam molds to produce iron and steel

castings.

Lost Wax Investment Casting Pattern

This is the iron patterns used for lost wax

investment casting method. The foundries use it to make wax molds,

then use the wax molds and water glass materials to make steel

castings.

Cast

Metal Parts

These are some cast metal parts made by

various casting methods.

This is the manhole castings made by manual

green sand casting method. The material is grey cast iron.

This is the ductile iron castings made by

furan resin sand casting method.

This is the small stove burner heads made

by shell molding method. The material is gray cast iron.

This is the manifold castings made by shell

and core molding method. The material is grey iron.

The is the steel casting, valve bodies made

by sand casting method.

The is the alloy steel castings made by

lost wax investment casting method.

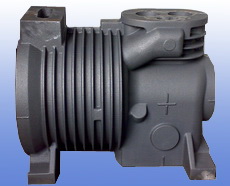

This is the aluminum alloy castings made by

die casting method.

Home |

More Articles |