| |

Cast Iron Housing

Cast iron housing means the iron castings

such as tractor gear boxes,

pump bodies and other casings

just like a box or house shapes.

Ductile iron series housings weight 40% less in comparison with

standard housings made with gray cast iron. Ductile iron series

housings are approximately 30% stronger than standard housings made

with gray cast iron. Therefore, ductile iron has been more widely

used for cast iron housings.

Ductile cast iron housings are designed to be lighter and more

compact than gray cast iron units. Since ductile cast iron is

stronger, these compact castings can commonly replace standard

castings. So, ductile cast iron parts will perform well in harsh

environments. As with all housed units, before applying, please

check the allowable load limit, bearing life and safety factors.

Housing Material

The material of cast iron housing basically includes ductile iron

and grey iron.

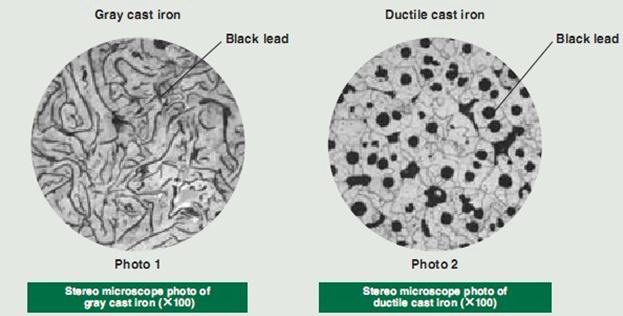

The housing material for the current standard bearing units is gray

cast iron (FC200). The FC200 material contains black lead and

graphite distributed as show in photo 1. When heavy shock loads are

applied to the housing, cracks spread along the black lead/graphite

strands and the housing may fracture. In FCD450 material, the black

lead and graphite nodules are distributed as shown photo 2. This

black lead/graphite distribution can prevent the spreading of

cracks. Also the shock resistance at low temperature, FCD450 is

superior to that of FC200.

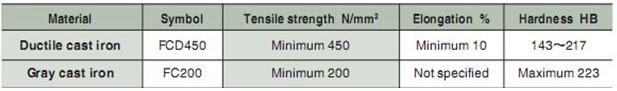

The following is the comparison for

characteristics of ductile iron and gray iron for housing castings.

Production Process

Normally, the shell molding process will be the most suitable

casting process for small housing products, however, it is more

costly than green sand casting process. As for the large casting

process, the resin sand casting process will be the most suitable

one in order to keep the good surface quality and dimensions.

Home |

More Articles |

|