| |

ASTM A48 Class 25 Cast Iron

ASTM A48 class 25 is a material grade of

gray cast iron in USA, which is higher than class 20, but lower than

class 30. Its UNS number is F11701. There are four specific grades

as ASTM A48 class 25A, 25B, 25C

and 25S.

Mechanical Properties of A48 Class 25 Cast Iron:

Its minimum tensile strength is 172 Mpa.

The gray cast iron is

brittle, so there is no requirements to yield strength and

elongation. Its hardness range is BH 170-229.

Although gray iron has bad tensile

strength, but their production costs are low, and easily

manufactured, moreover, this material has good Vibration reduction,

abrasive resistance, and low notch sensitivity. In addition, they

could be machined easily.

Chemical Composition of A48 Class 25 Cast Iron:

C%: 3.20-3.50, Si%: 1.60-2.40, Mn%: 0.60-0.90, P% ≤ 0.20, S% ≤ 0.15,

CE: 4.00-4.25.

We have talked about this issue for many

times in the past. In all international standards, there is no

compulsive stipulation to the chemical composition range. This is

very different with cast steel. As for gray iron and ductile iron,

the chemical composition is just for reference. The iron foundries

could adjust the composition as long as the mechanical properties

could meet the requirements.

Heat Treatment of ASTM A48 Class 25 Gray Iron:

The heat treatment can not change the structure of graphite, so can

not improve their mechanical properties, however, the annealing

treatment could reduce the internal force, and chilling

organization, stable the deformation, and improve the abrasive

resistance. However, the heat treatment will cause more production

costs, so most of grey iron castings will not be heat treated,

unless some special application.

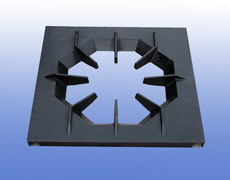

Main Application of ASTM A48 Class 25 Gray Iron:

Class 25 gray iron could be used to produce casting parts as machine

base, frames, supports, cases, machine body, bearing support,

foundation plates, belt pulley, end caps, pump bodies, valve bodies,

pipe fittings, fly wheels, gears etc.

The followings are some casting products

manufactured by our iron foundry.

Home |

More Articles |

|