| |

A 247 - 67 Standard of Test Method

for Evaluating the Microstructure of Graphite in Iron Castings

The microstructure of graphite is very

important for inspection to the quality of

iron castings,

especially for cast iron parts

on automotive, engineer machinery. Therefore, many clients may

require the iron foundries

and cast iron suppliers to inspect microstructure of castings and

show the graphite form in the firm inspection report.

This standard covers the classification of graphite in

cast irons in terms of type,

distribution, and size, and the test method is intended to be

applicable for all iron-carbon alloys containing graphite particles,

and may be applied to gray irons,

malleable irons, and the

ductile (nodular) irons.

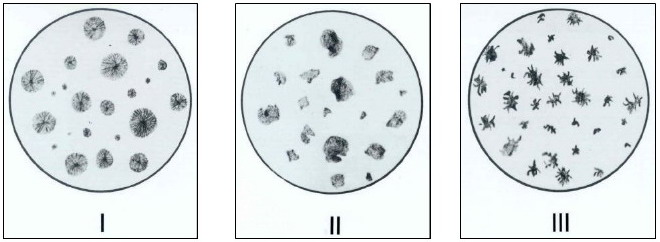

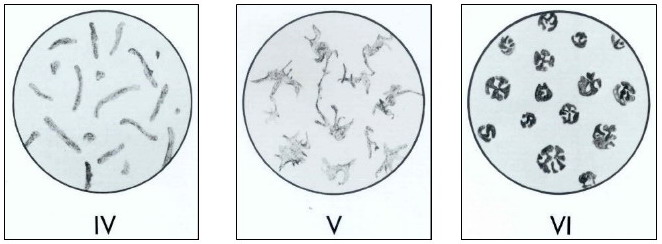

Classification of graphite form

By scanning the polished specimen under the microscope, then the

inspector can observe the graphite forms in the micro-structure,

then evaluate the spheroidizing level or inspect the graphite forms

correspond to type designations.

The following seven types are the main reprehensive forms for grey

iron, malleable iron and ductile irons.

Type I is the normal and usually desirable graphite form in ductile

iron, although the presence of Type Ⅱ graphite forms has little or

on adverse effect on properties.

Type Ⅲ is the graphite form most often seen in malleable iron

castings after annealing. Some malleable irons may contain Types Ⅰ

or Ⅱ graphite particles also.

Graphite forms represented by Types Ⅳ to Ⅵ

often occur in ductile iron in conjunction with Type I and Ⅱ. The

percentages of each graphite type are estimated by observation, or

better, by counting the particles of each type. Types present in a

sample are to be reported in percentages to total 100. Any

convenient magnification that clearly reveals the graphite form may

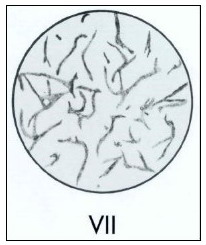

be used. Type Ⅶ is the flake graphite form usually seen in gray

iron.

Home |

More Articles |

|