| |

EN-GJS-450-10, ASTM A536

65-45-12, Ductile Iron, SG Iron

Chemical Composition, Mechanical and Physical Properties

EN-GJS-450-10 (ASTM A536 65-45-12) is an

excellent ductile iron (SG iron) material grade. It has

comparatively high tensile strength, high elongation, and good

impact resistance. So,

this cast iron grade has very wide application.

Our dandong foundry has producing this

material grades for many years, and herein, we share its chemical

composition, mechanical and physical properties.

1. Equivalent

Material Grades of Ductile

Iron GJS-450

The equivalent grades of EN 1563

EN-GJS-450-10 are ASTM A536 65-45-12, FCD400, FGS400, FGE42-12,

FNG42-12, GS400-12, 60-42-10, QT450-10, ISO 450-10. Although some

grades just require elongation 10%, the iron foundries just need to

adjust the chemical composition to make the elongation a little

higher, then they will meet the requirement.

2.

Chemical Composition of SG Iron, Ductile Iron GJS-450

According to all international material

standards, the chemical composition should not be taken as the

inspection standard, unless the clients have special requirements.

However, by our experience, the

approximate chemical components of ductile iron GJS-450 should be

as C: 3.50-4.00, Si: 2.20-2.90, Mn: 0.3-0.6, P: 0.03-0.06, S:

0.02-0.040, Mg: 0.020-0.060.

3. Mechanical &

Physical Properties of Ductile Iron GJS-450

Tensile Strength ≥ 450 MPa. Yield

Strength ≥ 310 MPa. Elongation ≥ 10%.

As for A536 65-45-12, its elongation ≥

12%. Other requirements will be as same as GJS-450.

There is no strict stipulation to the

hardness of GJS-450, however, normal hardness range should be 160 -

210 BH (Brinell Hardness).

4.

Main Application of Ductile Iron GJS-450

Because of the comparatively high

elongation, this GJS-450 ductile iron could be used for producing

impact resistance casting parts. In addition, it has good low

temperature impact resistance, and good hardness, so it has been

used for producing plow point, blade plough, furrow plough, furrow

plough, plough pile, differential shell, valve body, and high

pressure cylinder.

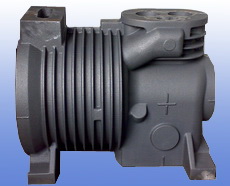

The followings are some ductile iron

castings we produced.

Home |

More Articles |

|