| |

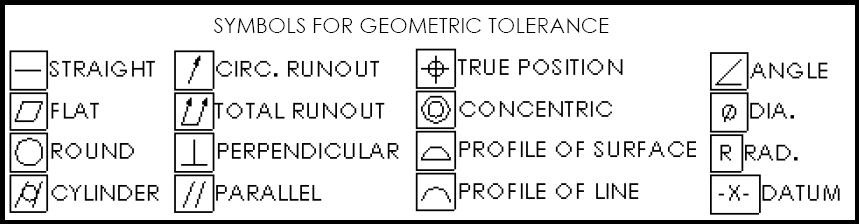

Symbols for Geometric Tolerance

The followings are the normal symbols for

geometric tolerance shown on the drawings of iron and steel

castings. We just briefly introduce their meanings, and hope they

could be useful for buyers and suppliers to better understand the

drawings.

Straight – straightness, indicating the tolerance for

straightness to one edge or to one line.

Flat – flatness, indicating the flatness to one surface.

Higher flat will mean the surface must be very flat. Usually this

tolerance is for the rough surface of metal castings.

Round – ovality, indicating how round for one round surface.

If round tolerance is high, then it will mean the ellipse and

irregular circle will not be allowable.

Cylinder – it is for the tolerance to the cylinder, which is

similar with the round, but just for the how cylinder, not just for

one circle.

Circle Runout – this is one simple tolerance for indicating

the tolerance when round part rotates by one standard axle. High

circle runout means the part needs to rotate perfectly by the

standard axle.

Total Runout – this is the higher tolerance for indicating

the tolerance when round part rotates by one standard axle. It is

hard to explain by English, but it will mean this part needs to

rotate perfectly.

Perpendicular – this indicates two lines or two surfaces need

to be vertical.

Parallel – it means two lines or two surfaces should be

paralleled.

True Position – it means how far for one axle line or center

position to deviate their theoretical positions.

Concentric – it means how the axles of two circles deviate

each other.

Profile of Surface – it means the real surface deviate the

theoretical surface.

Profile of Line – it means the line deviate the theoretical

line.

Angle – it means the allowable angle tolerance.

Diameter – it means the max. dimensional tolerance for one

diameter.

Radius – it means the max. radius deviation.

Datum – reference, standard, or reference face, standard

face.

Home |

More Articles |

|