| |

How to control the casting quality of cast iron and

cast steel products made in China

I have worked in China foundries for years

as a marketing manager, so I have met many quality complains and

problems, so I am thinking how to control the cast iron and cast

steel casting quality.

Many importer and trading companies were heating to import metal

castings parts, especially cast iron and cast steel casting parts,

this is because there are many quality problems with them. Even if

you find a very good foundry as supplier in China, looks like

quality problems will happen anyway.

The basic reasons are two aspects. One is the casting production

processes are very complex and there are many aspects which will

affect the quality. Second reason is the workers’ skill and quality

is very low and different in China foundries. The working conditions

are bad in foundries, so only farmers and physical working man are

willing to work in this condition, so they will affect the stable

quality.

However, in India, their quality of workers will be worse than

Chinese, so you will have to import casting parts from China anyway,

then you will need to hear about the following suggestions to

control the quality.

1. REPORTS

Inspection reports are very effective and useful method to control

the quality of iron and steel castings. The reports will prove that

the foundries have performed the inspection, and they also promise

the casting quality as the reports.

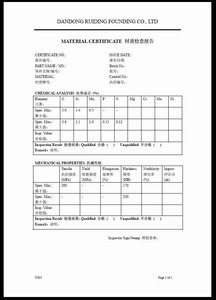

Material report includes chemical composition, and mechanical

properties, including tensile strength, yield strength, hardness,

nodular rate, etc.

Dimensional reports will show the inspection results to the

dimensions. Our Dandong Foundry also shows surface quality and other

inspection results on the dimensional reports.

2. TOOLING

Inspection tooling is very useful for the manufacturer to control

the quality. For example, if this metal casting part needs to

assemble with other parts, then if it is possible, please send these

parts to the manufacturer, so they can use them as the inspection

tools. Otherwise, suggest the foundries to make some inspection

tools for the key dimensions. For tapping thread, you could send

some No-Go gage to the foundries or tell them the exact types, so

they could buy them in China.

Personally, I think inspection tool will be more useful to control

the dimensions than dimensional reports.

3. PHOTOS

If you want to check the surface quality, painting and packing, then

you could require the Chinese foundries to take some photos for the

metal castings. Please believe me that they are useful. Many of our

clients discussed quality issues with us by photos with denotation,

which has helped us to solve many problems.

4. ASK FRIENDS TO INSPECT

If you want to inspect the casting quality or want to survey a China

foundry, but you do not have time to do so, then you could ask one

of your suppliers to help you to do so. I have helped many clients

to do the factory investigation. After I review their Chinese website and calling to their contact, I will make a personal opinion

to judge if they are cheater, if they are qualified, and if skillful

to complete the products of yours. If you want to inspect the casting quality or want to survey a China

foundry, but you do not have time to do so, then you could ask one

of your suppliers to help you to do so. I have helped many clients

to do the factory investigation. After I review their Chinese website and calling to their contact, I will make a personal opinion

to judge if they are cheater, if they are qualified, and if skillful

to complete the products of yours.

Sometimes, we can send an inspector to site to inspect the quality.

One aspect, we could inspect some problems. Second aspect, the

suppliers will notice that you have inspectors in China, so they

will control the quality stricter than normal.

5. ENTRUST THIRD PARTY INSPECTION

If you have lots of money, and inspection is very important for you,

then you could try to entrust the third party inspection company to

site inspecting. However, one disadvantage is very high cost,

another disadvantage is they can not find out the quality problems.

Most of Inspection Company or organization declared that they can

inspect quality, but actually, they just could do some simple

dimensional inspection. Even if they have some inspection devices,

such as UT inspector, their devices are not almighty, they can find

out some big quality problems, but can not find out small problems.

Our foundry does not have resistance to third party inspection,

moreover, during each time inspection, we can learn more knowledge

from them, and however, what I said is also the truth. I just said

the third party inspection is not almighty, and the result also

depends on their real capability, not as their propaganda.

In addition, please try to tell you supplier

how you will use these casting parts, sending some assembly drawings

or photos to them, this information will be the best for their

quality control. Many clients may think this is necessary, you just

need to meet the tolerance and requirements on the drawing, no need

to understand how we will use them. Actually, this is the biggest

mistake. This information will help the manufacturers to know the

key dimensions, the main requirements to surface quality, and inside

defects. Please, please believe me, this is very important.

Home |

More Articles |

|